Products

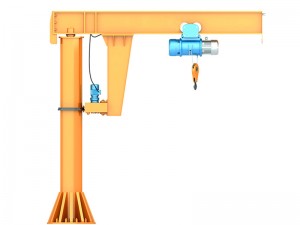

Workshop 3ton Motorized Fixed Pillar Jib Crane with Electric Hoist

Description

The Jib Crane is a type of crane that uses a mounted arm to lift, move and lower material. The arm, mounted either perpendicular to or an acute angle upwards from a column(pillar), may rotate along its central axis through a limited arc or a full circl. A column mounted jib crane is often used in industrial settings, like warehouses, to load and unload material.

Safety Features:

* Overload limiter

* Stroke limiter

* Bus Bar preventer plate

* Under-voltage protection

* Interlock protection device

- Capacities from 250 kgs to 5 Ton

- Standard span upto 20 feet

- 360 degree rotation

- Designed for permanent concrete foundation

- Base plates assembly is secured by means of anchor bolts to a prescribed reinforced concrete foundation, with the number of anchor bolts varying with the capacity of the tadano crane.

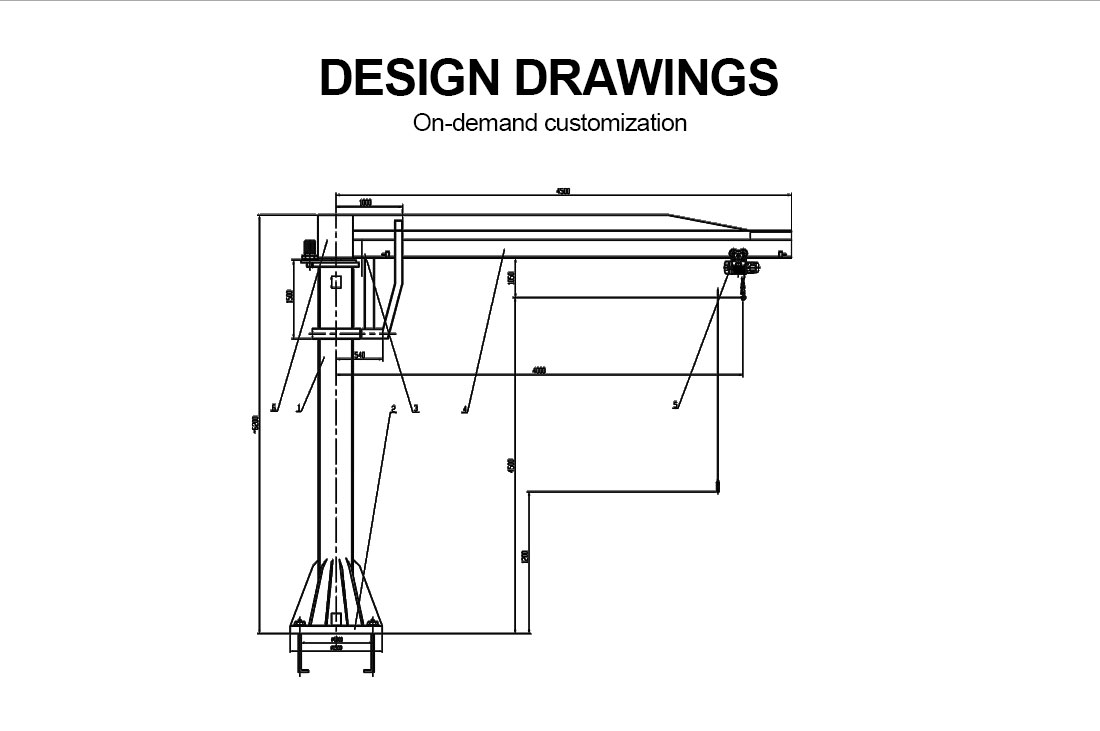

- The pipe or colomn is designed to give maximum strength and minimum

- deflection to resist bending, buckling and crushing

- The top bearing assembly utilizes a tapered roller bearing provided with

- grease fitting for proper lubrication.

Product Drawing

Technical Parameters

|

Lifting Capacity(t)

|

0.5

|

1

|

2

|

3

|

5

|

|

Span(m)

|

3-8

|

||||

|

Light Hight(m)

|

3-12

|

||||

|

Lifting speed( m/min)

|

8(0.8/8)

|

||||

|

Crba travelling speed

|

20(m/min)

|

||||

|

Crane travelling speed

|

0.6(m/min)

|

||||

|

Control Mode

|

Handle / remote control

|

||||

|

Working level

|

A3/A4/A5

|

||||

Why Choose Us

Complete

Models

Adequate

Nventory

Prompt

Delivery

Support

Customization

After-sales

Consultation

Attentive

Service

Easy to operate

Excellent performance,reasonable design, high work efficiency, saving time and effort

s

s

Reasonable structure

The whole machine has beautiful structure, good manufacturability, wide working space and stable operation

S

Support Customization

Can be customized according to needs

s

s

s

Packing&Shipping

PACKING AND DELIVERY TIME

We have a complete production security system and experienced workers to ensure timely or early delivery.

RESEARCH ANDDEVELOPMENT

Professional power.

BRAND

Strength ofthe factory.

PRODUCTION

Years ofexperience.

CUSTOM

Spot isenough.

Asia

10-15days

Middle East

15-25days

Africa

30-40days

Europe

30-40days

America

30-35days

By National Station exporting standard plywood box,wooden palletor in 20ft & 40ft Container.Or as per your demands.