Products

Top standard boat deck crane for maritime operations

description

A deck crane, also known as a boat crane, plays a crucial role in maritime operations. Its unique structural characteristics make it an indispensable tool for various tasks onboard ships.

The structural characteristics of a deck crane are designed specifically for marine environments. Unlike typical cranes such as gantry cranes or overhead cranes, a deck crane is mounted on the ship's deck, providing stability and flexibility during operations. Its pivotal feature is the slew ring, a circular bearing that allows the crane to rotate 360 degrees, facilitating precise load handling and maneuverability. Additionally, deck cranes are equipped with hydraulic or electric systems to control the lifting operations, ensuring smooth and efficient cargo transfer.

The significance of a deck crane in maritime operations cannot be overstated. It plays a key role in loading and unloading cargo, such as containers, machinery, and provisions, onto and off the ship. This increases the efficiency of port operations and reduces turnaround time, enabling ships to adhere to tight schedules. Moreover, deck cranes are instrumental in emergency situations, such as search and rescue operations or salvaging sunken ships, providing crucial lifting capabilities to retrieve or relocate items underwater.

Compared to traditional cranes used on land, deck cranes exhibit several notable differences in terms of their applicability and functionality. Firstly, deck cranes are specifically designed to withstand harsh marine environments, including saltwater corrosion and extreme weather conditions. The materials used in their construction are highly durable and resistant to deterioration, ensuring reliable performance even in challenging marine settings. Secondly, deck cranes are compact in size and can be maneuvered within tight spaces onboard a ship, making them suitable for limited working areas. Lastly, deck cranes are equipped with safety features and mechanisms to ensure secure cargo handling, as maritime operations demand utmost care and attention to avoid accidents or damage to goods.

technical parameters

| parameters of boat deck crane | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| item | unit | result | |||||||

| rated load | t | 0.5-20 | |||||||

| lifting speed | m/min | 10-15 | |||||||

| swing speed | m/min | 0.6-1 | |||||||

| lifting height | m | 30-40 | |||||||

| rotary range | º | 360 | |||||||

| working radius | 5-25 | ||||||||

| amplitude time | m | 60-120 | |||||||

| allowing inclination | trim.heel | 2°/5° | |||||||

| power | kw | 7.5-125 | |||||||

product details

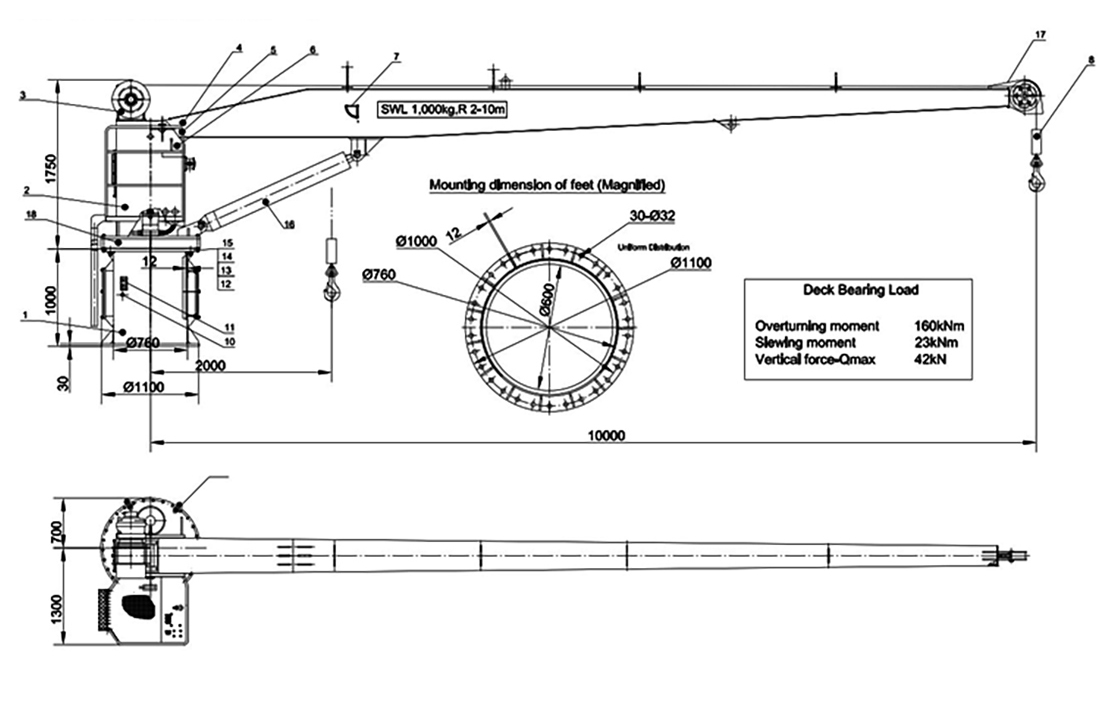

hydraulic telescope rane

be installed on the ship with the narrow, like

marine engineering service ship and small cargo

ships

swl:1-25ton

length of jib:10-25m

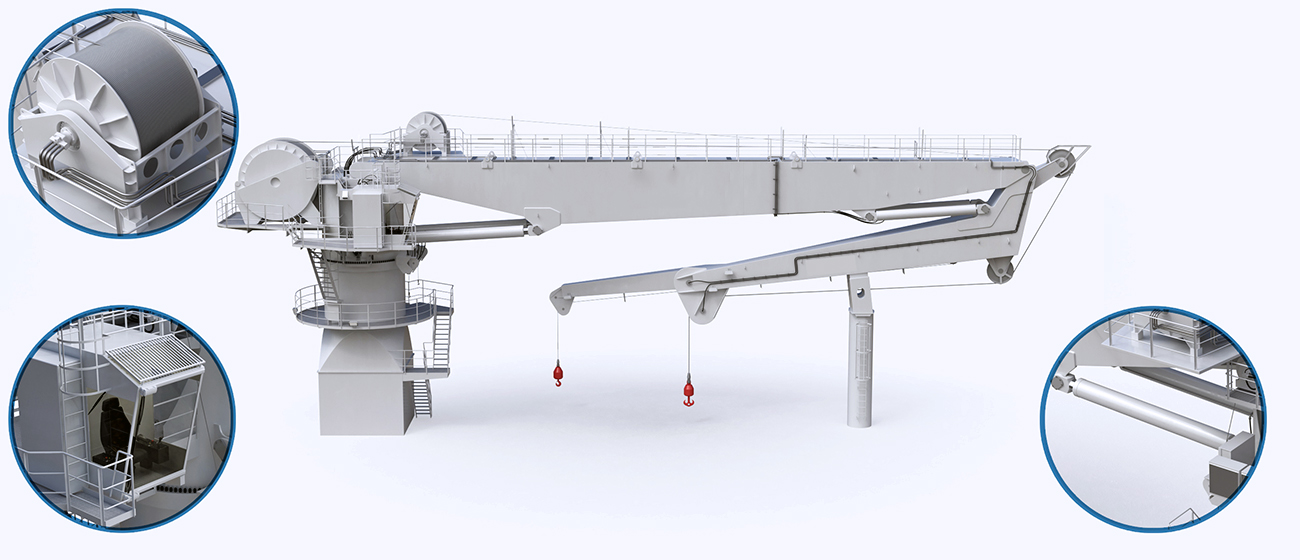

marine electrical hydraulic cargo crane

designed to unload goods in bulk carrier or

container vessel, controlled by electric type or

electric hydraulic type

swl:25-60ton

max.working radius:20-40m

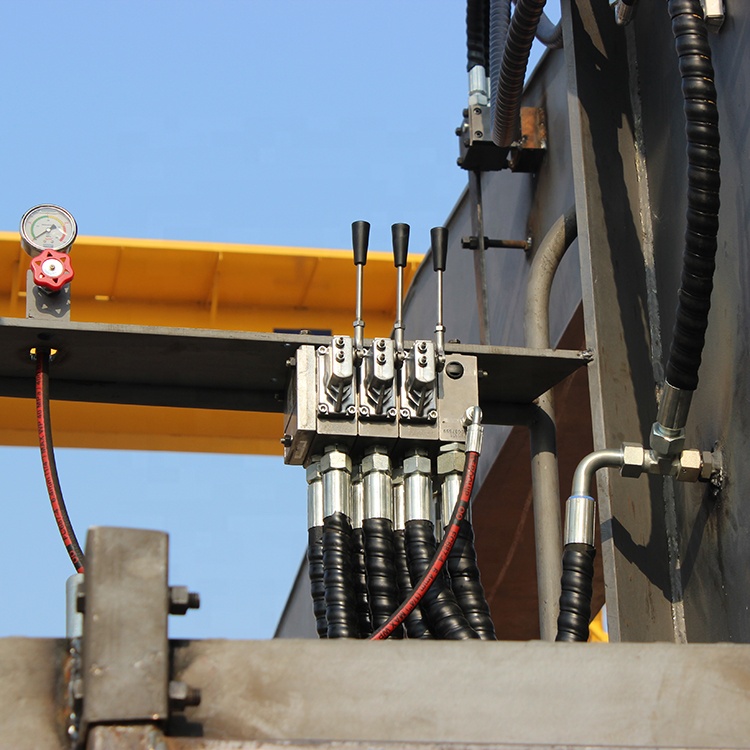

crane hydraulic pipeline

this crane is mounted on a tanker, mainly for ships transporting oil as well as lifting of doogs and other items, it is a common, ideal lifting equipment on the tanker.

providing you with the safest equipment

HYCrane VS Others

Our Material

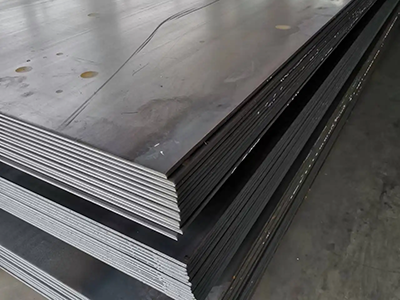

1. The raw material

procurement process is strict and

has been inspected by quality inspectors.

2. The materials used are all steel products from

major steel mills, and the quality is

guaranteed.

3. Strictly code into inventory.

1. Cut corners, originally used 8mm steel

plate,but used 6mm for customers.

2. As shown in the picture, old equipment is often

used for refurbishment.

3. Procurement of non-standard steel from small

manufacturers, product quality is unstable.

Other Brands

Our Motor

1. Motor reducer and brake

are three-in-one

structure

2. Low noise, stable operation and low maintenance

cost.

3. The built-in anti-drop chain can prevent

the bolts from being loosened, and avoid the

harm to the human body caused by the accidental fall

of the motor.

1.Old-style motors: It is noisy, easy to wear, short

service life, and high maintenance cost.

2. The price is low and the quality is very poor.

Other Brands

Our Wheels

All wheels are heat-treated and modulated, and the surface is coated with anti-rust oil to increase the aesthetics.

1. Do not use splash fire modulation, easy to

rust.

2. Poor bearing capacity and short service life.

3. Low price.

Other Brands

our controller

our inverters make the crane run more stable and safe, and make the maintenance of the more intelligent and easy.

the self-adjusting function of inverter allows motor to self-adjust its power output according to the load of the hoisted object at any time, thereby saving the factory costs.

the control method of the ordinary contactor allows the crane to reach the maximum power after it is started, which not only causes the whole structure of the crane to shake to a certain degree at the moment of starting, but also slowly loses the service life of the motor.

other brands

transport

- packing and delivery time

- we have a complete production security system and experienced workers to ensure timely or early delivery.

-

research and development

- professional power

-

brand

- strength of the factory.

-

production

- years of experience.

-

custom

- spot is enough.

-

asia

- 10-15days

-

middle east

- 15-25days

-

africa

- 30-40days

-

europe

- 30-40days

-

america

- 30-35days

By national station exporting standard plywood box,wooden palletor in 20ft & 40ft container. Or as per your demands.