Products

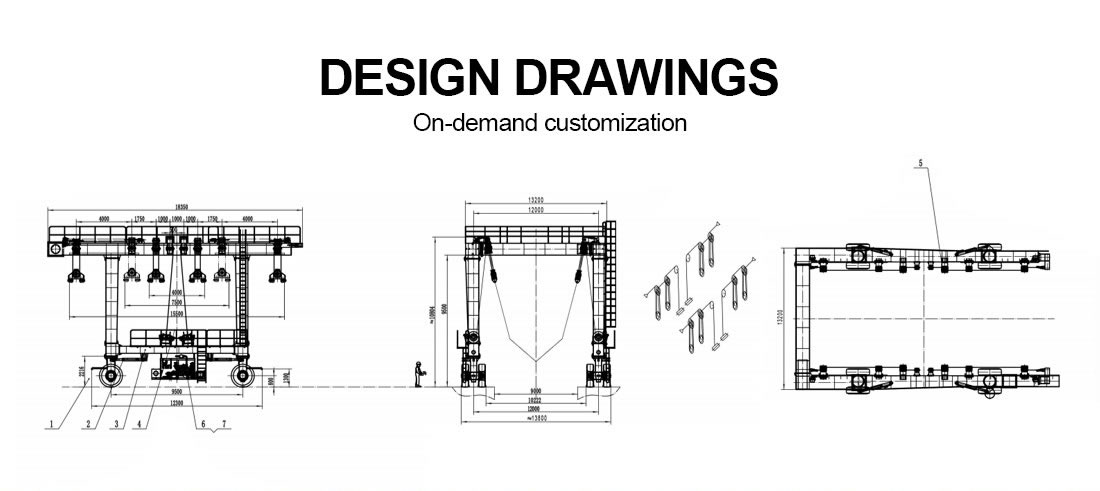

Robuster structure marine yacht lift with advanced design

description

The marine travel lift, also known as a yacht lift, is a specialized lifting equipment designed for the purpose of handling and transporting yachts and boats in the marine industry. Its primary function is to safely lift and move vessels from the water, whether it is for maintenance, repair, or storage purposes.

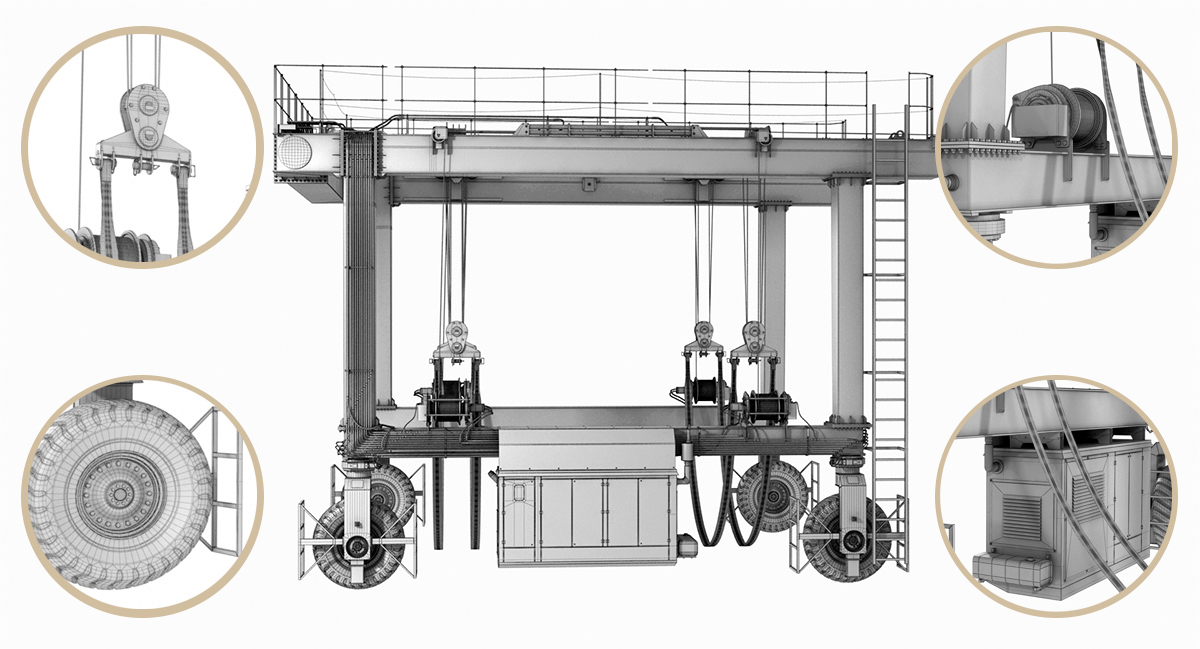

One of the significant features of a marine travel lift is its robust and durable structure. It typically consists of a solid steel frame with multiple lifting points strategically placed to ensure even weight distribution and stability during the lifting process. The frame is commonly equipped with hydraulic or electric-powered winches and wire ropes, allowing for precise and controlled movements.

In addition to its strong structure, a marine travel lift is equipped with various supporting components to enhance its functionality. These may include adjustable lifting slings or straps, which can accommodate vessels of different sizes and shapes. Furthermore, some lift models are equipped with additional features such as adjustable lifting arms or spreaders, allowing for even distribution of the lifting load.

The usage of a marine travel lift extends beyond simple lifting and transportation. It also plays a crucial role in the overall maintenance and servicing of yachts and boats. For instance, the lift can be used to inspect and clean the hull, replace or repair propellers and shafts, or even apply anti-fouling coatings. Additionally, the lift can facilitate the launching and docking of vessels, ensuring a safe and efficient transition between land and water.

technical parameters

| parameters of marine travel lift | |||||||||

|---|---|---|---|---|---|---|---|---|---|

|

type

|

safety working

load (n) |

max working

rate (m) |

min working

rate (m) |

hoisting

speed (m/min) |

slewing

speed (r/min) |

luffing

time (s) |

hoisting

height (m) |

slewing

angle |

|

|

power

(kw) |

sq1

|

10

|

6~12

|

1.3~2.6

|

15

|

1

|

60

|

30

|

|

|

2/5

|

7.5

|

sq1.5

|

15

|

8~14

|

1.7~3

|

15

|

1

|

60

|

|

|

360

|

2/5

|

11

|

sq2

|

20

|

5~15

|

1.1~3.2

|

15

|

1

|

|

|

30

|

360

|

2/5

|

15

|

sq3

|

30

|

8~18

|

1.7~3.8

|

15

|

|

|

70

|

30

|

360

|

2/5

|

22

|

sq5

|

50

|

12~20

|

2.5~4.2

|

|

|

0.75

|

80

|

30

|

360

|

2/5

|

37

|

sq8

|

80

|

12~20

|

|

|

15

|

0.75

|

100

|

30

|

360

|

2/5

|

55

|

sq10

|

100

|

|

|

2.5~4.2

|

15

|

0.75

|

110

|

30

|

360

|

2/5

|

75

|

sq15

|

|

|

12~20

|

2.5~4.2

|

15

|

0.6

|

110

|

30

|

360

|

2/5

|

90

|

|

|

200

|

16~25

|

3.2~5.3

|

15

|

0.6

|

120

|

35

|

270

|

2/5

|

|

|

sq25

|

250

|

20~30

|

3.2~6.3

|

15

|

0.5

|

130

|

40

|

270

|

|

|

90*2

|

sq30

|

300

|

30

|

3.2~6.3

|

15

|

0.4

|

140

|

40

|

|

|

2/5

|

90*2

|

sq35

|

350

|

20~35

|

4.2~7.4

|

15

|

0.5

|

150

|

|

|

360

|

2/5

|

110*2

|

sq40

|

400

|

20~35

|

4.2~7.4

|

15

|

0.5

|

|

product details

DOOR FRAME

The door frame have single main type and double girder type two kinds of for reasonable use of material,the main variable cress-section of the optimization

FIRM BELT

Low cost on the daily operation, it adopts the soft and firm belt to ensure there is no harm to the boat when hoisting.

TRAVELING MECHANISM

It can realize12 walking funcyions as straight line,transverse line, in-place rotayion and Ackerman turning ect.

CRANE CABIN

The high-strength frame is by high-quality profile,and the high- quality cold rolling plate is finished by the CNC machine.

LIFTING MECHANISM

Lifting mechanism adopts the load-sensitive hydraulic system, the lifting point distance can be adjusted to keep the simultaneous lifting of multi-lift points and output.

ELECTRIC SYSTEM

Electrical system uses PLC frequency adjustment which can easily control every mechanism.

Fine Workmanship

Low

Noise

Fine

Workmanship

Spot

Wholesale

Excellent

Material

Quality

Assurance

After-Sale

Service

application

- it is used in many fields.

- satisfy the users' choice under different condition.

- usage: used in shipyard, outdoor repair shop, yacht lifting,storehouse, to meet the daily lifting work.

- shipyard

- outdoor repair shop

- yacht lifting

- storehouse

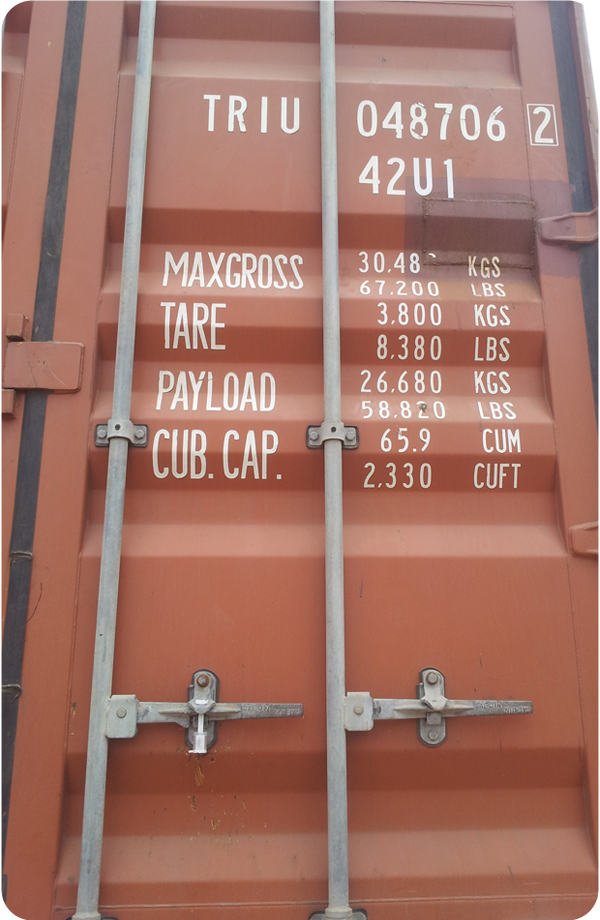

transport

- packing and delivery time

- we have a complete production security system and experienced workers to ensure timely or early delivery.

-

research and development

- professional power

-

brand

- strength of the factory.

-

production

- years of experience.

-

custom

- spot is enough.

-

asia

- 10-15days

-

middle east

- 15-25days

-

africa

- 30-40days

-

europe

- 30-40days

-

america

- 30-35days

By national station exporting standard plywood box,wooden palletor in 20ft & 40ft container. Or as per your demands.