Products

Promotion price sts container quay crane for portal

description

The quay side container crane, also known as a ship-to-shore crane, is an essential piece of equipment in port operations. Its primary purpose is to efficiently load and unload containers from ships at the quayside. This massive crane plays a pivotal role in the efficient transfer of goods between ships and land, facilitating international trade and contributing to global supply chains.

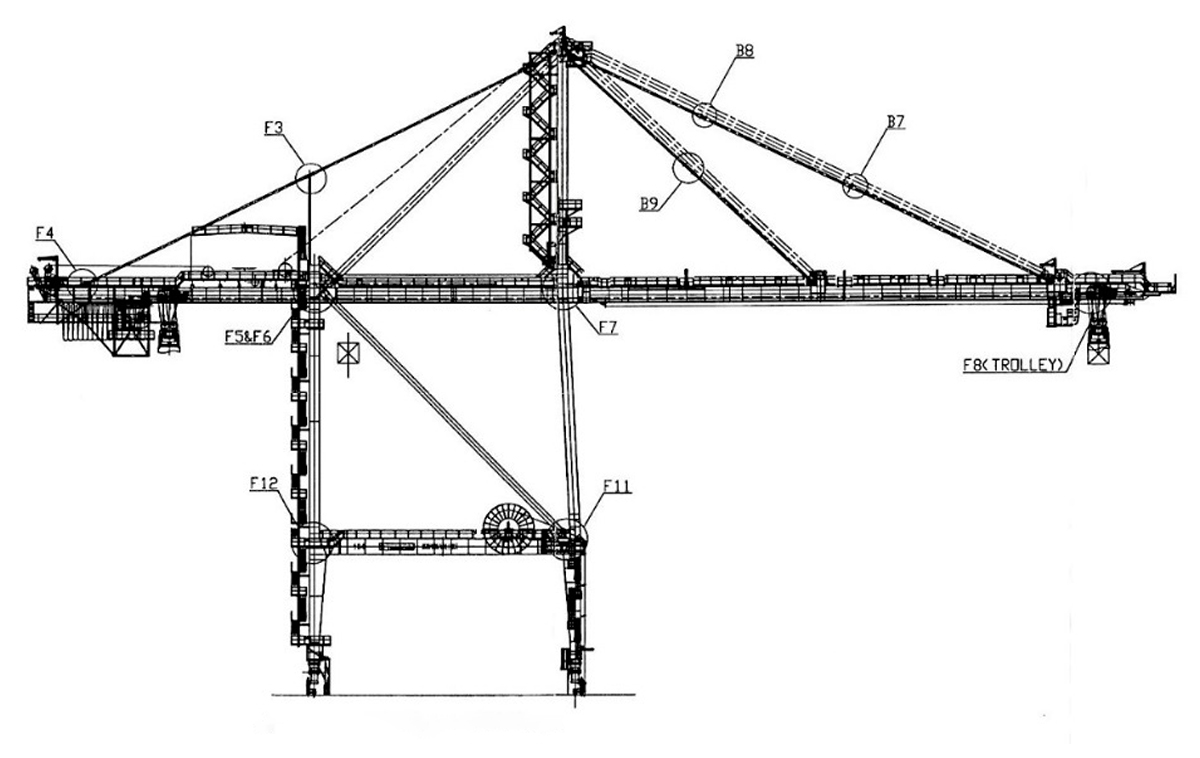

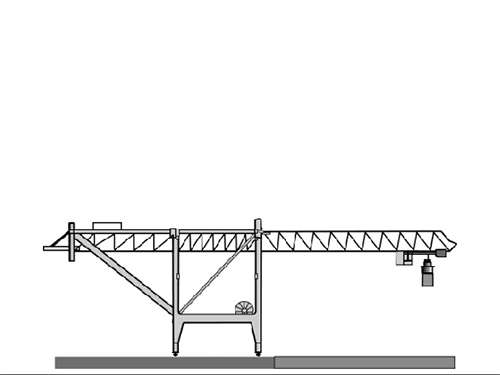

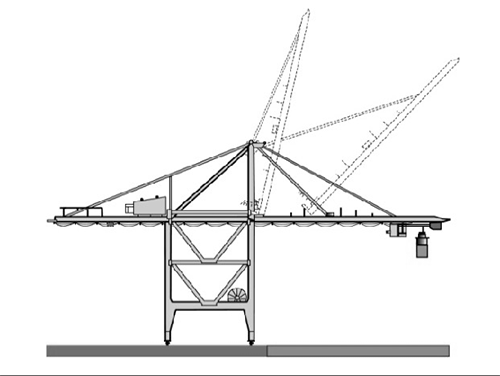

Now, let's dive deeper into the structural characteristics that make the quay side container crane an impressive feat of engineering. At its core, this crane is built for strength and stability, as it needs to handle heavy loads and withstand the challenges of working near the sea. Its structure typically consists of a tall steel tower, mounted on a sturdy foundation. The tower supports a horizontal boom known as a jib, which extends outwards over the water. This jib is capable of traversing back and forth along the length of the quay, enabling the crane to reach containers positioned at different locations on the ship.

To lift and lower containers, the quay side container crane is equipped with multiple hoisting mechanisms. These mechanisms typically include powerful winches with wire ropes. The ropes are attached to the lifting hooks or spreader beams, allowing for controlled vertical movement of the containers. The crane's lifting capacity is carefully engineered to handle the weight of fully loaded containers, ensuring safe and efficient operations.

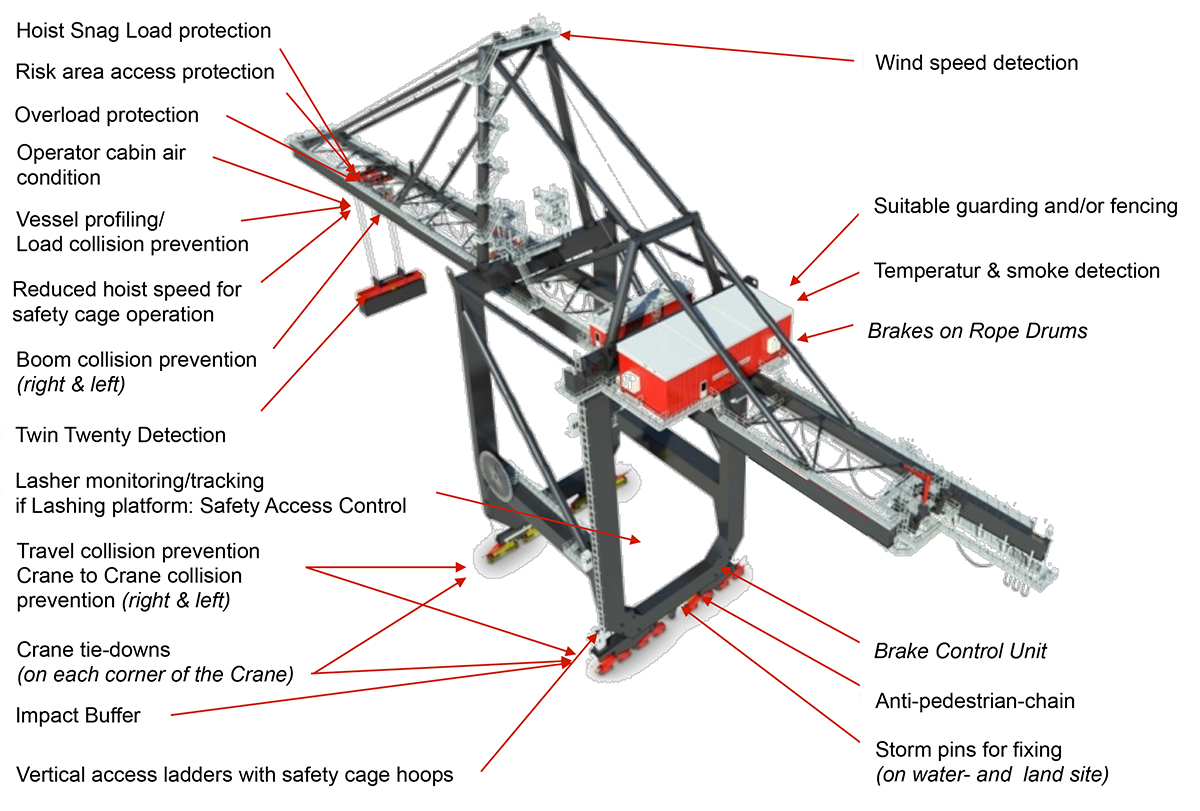

Safety is paramount in the operation of a quay side container crane. These cranes are equipped with a multitude of safety devices and protocols. They often feature anti-sway systems to minimize any swaying or pendulum movement of the load. Additionally, limit switches and load sensors are in place to prevent overloading, ensuring that the crane operates within its safe working limits. This focus on safety ensures the protection of both personnel and cargo during lifting operations.

technical parameters

| parameters of sts container quay crane | |||||||

|---|---|---|---|---|---|---|---|

| rated load | under spreader | 40t | |||||

| under headlock | 50t | ||||||

| distance parameter | out reach | 35m | |||||

| rail gauge | 16m | ||||||

| back reach | 12m | ||||||

| hoisting height | above rail | 22m | |||||

| below rail | 12m | ||||||

| speed | hoisting | rated load | 30m/min | ||||

| empty spreader | 60m/min | ||||||

| trolley travel | 150m/min | ||||||

| gantry travel | 30m/min | ||||||

| boom hoist | 6min/single stroke | ||||||

| spreader skew | left and right inclination | ±3° | |||||

| fore-and-aft inclination | ±5° | ||||||

| plane rotating | ±5° | ||||||

| wheel load | working condition | 400KN | |||||

| non-working condition | 400KN | ||||||

| power | 10kV 50 Hz | ||||||

product details

First-class brand parts

Variable speed

Cabin Operated

Soft starter

Slipring motors

Provide custome service

PLC automatic Control system

High quality carbon steel Q345

| main details | ||

|---|---|---|

| Load capacity: | 30t-60t | (we can supply 30 ton to 60 ton,more other capacity you can learn from other project) |

| Span: | max 22m | (Standard we could supply span max to 22m, please contac our sales manager for more details) |

| Lift height: | 20m-40m | (We can supply 20 m to 40 m,also we can design as your request ) |

HYCrane VS Others

Our Material

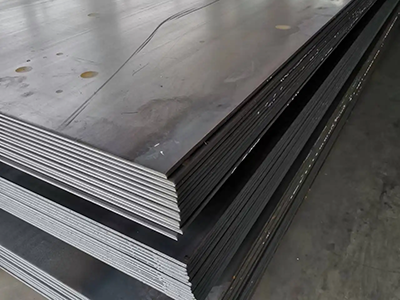

1. The raw material

procurement process is strict and

has been inspected by quality inspectors.

2. The materials used are all steel products from

major steel mills, and the quality is

guaranteed.

3. Strictly code into inventory.

1. Cut corners, originally used 8mm steel

plate,but used 6mm for customers.

2. As shown in the picture, old equipment is often

used for refurbishment.

3. Procurement of non-standard steel from small

manufacturers, product quality is unstable.

Other Brands

Our Motor

1. Motor reducer and brake

are three-in-one

structure

2. Low noise, stable operation and low maintenance

cost.

3. The built-in anti-drop chain can prevent

the bolts from being loosened, and avoid the

harm to the human body caused by the accidental fall

of the motor.

1.Old-style motors: It is noisy, easy to wear, short

service life, and high maintenance cost.

2. The price is low and the quality is very poor.

Other Brands

Our Wheels

All wheels are heat-treated and modulated, and the surface is coated with anti-rust oil to increase the aesthetics.

1. Do not use splash fire modulation, easy to

rust.

2. Poor bearing capacity and short service life.

3. Low price.

Other Brands

our controller

our inverters make the crane run more stable and safe, and make the maintenance of the more intelligent and easy.

the self-adjusting function of inverter allows motor to self-adjust its power output according to the load of the hoisted object at any time, thereby saving the factory costs.

the control method of the ordinary contactor allows the crane to reach the maximum power after it is started, which not only causes the whole structure of the crane to shake to a certain degree at the moment of starting, but also slowly loses the service life of the motor.

other brands

transport

- packing and delivery time

- we have a complete production security system and experienced workers to ensure timely or early delivery.

-

research and development

- professional power

-

brand

- strength of the factory.

-

production

- years of experience.

-

custom

- spot is enough.

-

asia

- 10-15days

-

middle east

- 15-25days

-

africa

- 30-40days

-

europe

- 30-40days

-

america

- 30-35days

By national station exporting standard plywood box,wooden palletor in 20ft & 40ft container. Or as per your demands.