Jib cranes are a popular choice for material handling and lifting operations in a variety of industries. They come in different types, including wall-mounted jib cranes and floor-mounted jib cranes, each with unique advantages and applications.

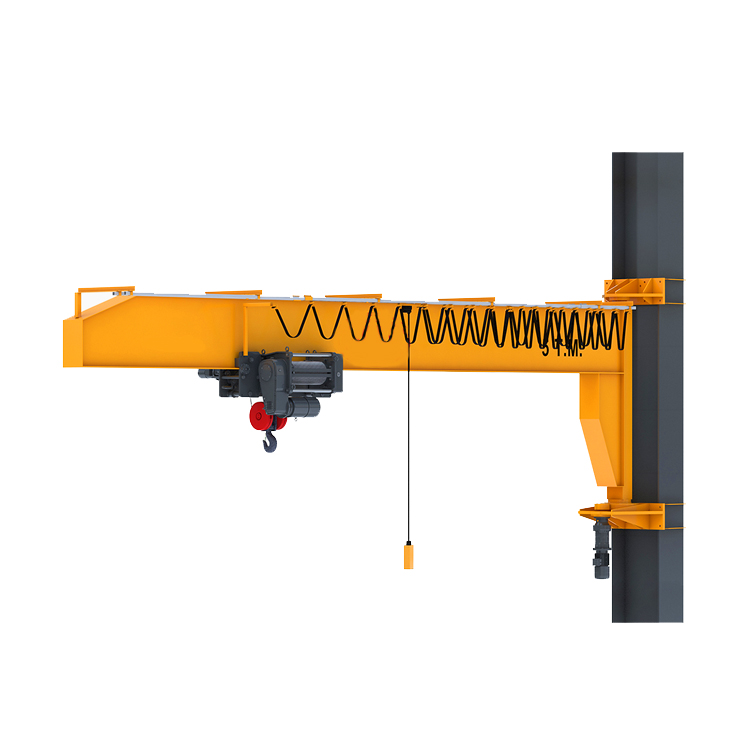

Wall-mounted jib cranes are fixed to a wall or support structure and are ideal for areas with limited floor space. They are commonly used in workshops, warehouses and manufacturing facilities where mobility and precision are critical. These cranes can rotate 180 degrees to efficiently lift and position heavy objects in specific areas.

Floor-standing jib cranes are mounted on the floor and offer 360-degree rotation. This type of jib crane is suitable for larger work areas and outdoor applications such as loading docks, construction sites, and shipping yards. Compared to wall-mounted jib cranes, floor-mounted jib cranes offer versatility and can handle heavier loads.

Jib cranes are mainly used in manufacturing, construction, logistics, transportation and other industries. In manufacturing plants, jib cranes are used to lift and move materials during the production process. They are also commonly found in warehouses and distribution centers for loading and unloading goods. In the construction industry, jib cranes are used to lift heavy equipment and construction materials to different levels of a structure. Additionally, jib cranes play a vital role in the transportation industry in loading and unloading cargo from trucks and ships.

The versatility of jib cranes makes them an essential lifting solution in a variety of work environments. They can be customized to meet specific lifting requirements and are available in different configurations to suit different applications. Whether a wall-mounted jib crane for compact workspaces or a floor-mounted jib crane for heavy-duty lifting, these cranes deliver efficient, safe and reliable performance in material handling operations.

Post time: Jul-03-2024