Products

Multifunctional promotion price straddle carrier for port

Description

Welcome to the advanced logistics world of our revolutionary

straddle carrier. Our straddle carriers are designed with

cutting-edge technology to provide unrivaled efficiency and

flexibility when moving containers and heavy loads within port

terminals and distribution centers. With their superior design,

state-of-the-art features and highest reliability, our straddle

carriers are the ultimate solution to increase the productivity of

your operation and maximize profitability.

A straddle carrier is a special heavy-duty vehicle used in the

logistics and transportation industry. It is specially designed to

handle containers and heavy loads with the utmost precision and

efficiency. Equipped with powerful engines and advanced hydraulic

systems, our straddle carriers can safely lift and transport

containers up to XX tons, allowing for seamless operations within

port terminals and distribution centers.

One of the key features of our straddle carriers is their

exceptional maneuverability. The straddle carrier features an

advanced wheel configuration that allows it to easily maneuver

through tight spaces and over uneven surfaces. Its wide reach

capabilities ensure that no area is off-limits, allowing for maximum

accessibility and flexibility when loading and unloading containers

on ships and trucks.

Our straddle carriers also boast an impressive control system that

allows the operator to perform operations with utmost precision. The

ergonomic cab design provides the operator with a clear view of

their surroundings, ensuring safe and efficient operation at all

times. Equipped with intuitive controls and innovative technology,

the straddle carrier is easy to use and minimizes the risk of

accidents or cargo damage.

Additionally, our straddle carriers are equipped with advanced

safety features. Anti-collision systems and sensors ensure vehicles

are always aware of their surroundings, reducing the risk of

accidents and collisions. Additionally, straddle carriers are

designed to withstand harsh weather conditions and heavy loads,

guaranteeing long-lasting performance and reducing maintenance

costs.

By investing in our straddle carriers, you can experience simplified

operations, increased productivity and enhanced profitability.

Transform your logistics operations with the power and versatility

of our advanced straddle carriers. It is the ultimate solution for

cost-effective container handling, ensuring your business stays

ahead in a competitive market.

Features of Straddle Carrier

● Easy to operate wireless remote control real-time

operation with two hands handle to achieve unlimited

vision.

● Small size, good mobility, free access to

warehouse and workshop doors.

● Weighing device and the safety protection system

of digital display height limiter.

● PLC program control design of the whole

electrical system.

● According to the requirements of users,

non-standard customized design and manufacturing.

● With wide wheel surface and high elastic coating

steel, the design of wheel reduces the requirements

of the ground road.

● The speed of the whole machine can be adjusted to

achieve zero speed braking when traveling, without

braking maintenance.

● All kinds of special custom designed lifting

appliances (non-standard, automatic, container

special lifting appliances, etc.) meet the

requirements of multiple varieties and multiple

operations.

● High reliability.

● Rated lifting capacity: 5 tons, 10 tons, 20 tons,

40 tons, 80 tons.

● The efficiency of loading, unloading, handling and

stacking of super wide and super heavy objects is

high.

● Wide range of use, low price, low operating cost

and fast return on investment.

● The design of the fully hydraulic driven wheels

ensures maximum stability.

● The small turning radius can realize the pivot

turning, and has the maximum traffic capacity in the

narrow aisle space.

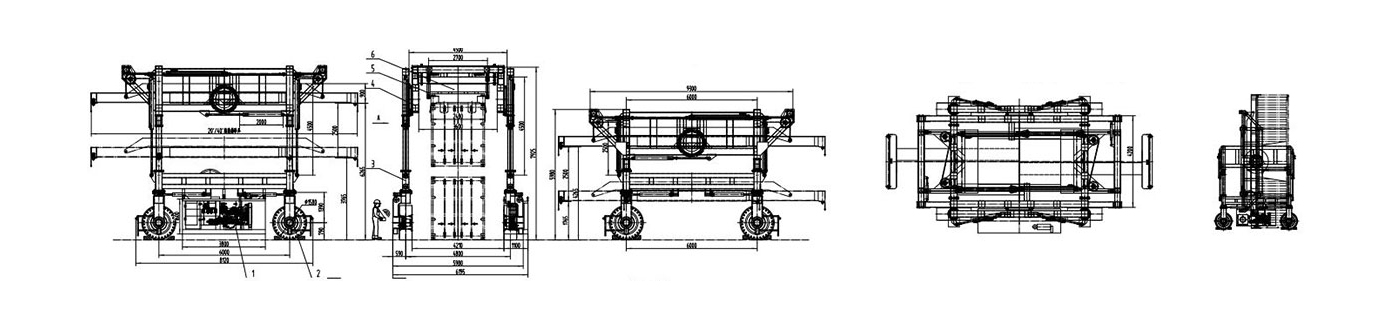

Schematic Drawing

Technical Parameters

| Parameters of Straddle Carrier | |||||||

|---|---|---|---|---|---|---|---|

| Product specification | 250t × 60m | 300t × 108m | 600t × 60m | ||||

| Working class | A5 | ||||||

| Capacity | Coommon lifting | t | 250 | 200 | 600 | ||

| Turning over | t | 200 | 200 | 400 | |||

| Span | m | 60 | 108 | 60 | |||

| Hoisting height | m | 48 | 70 | Above rail 40 Below rail 5 | |||

| Upper trolley | Capacity | t | 100 × 2 | 100 × 2 | 200 × 2 | ||

| Hoisting speed | m/min | 0.5-5-10 | 0.5-5-10 | 0.4-4-8 | |||

| Traveling speed | 1~28.5 | 3~30 | 1~25 | ||||

| Lower trolley | Capacity | Main hook | t | 100 | 150 | 300 | |

| Sub hook | 20 | 20 | 32 | ||||

| Hoisting speed | Main hook | m/min | 0.5-5-10 | 0.5-5-10 | 0.4-4-8 | ||

| Sub hook | 10 | 10 | 10 | ||||

| Traveling speed | 1~26.5 | 3~30 | 1~25 | ||||

| Maintenance hoist | Capacity | t | 5 | 5 | 5 | ||

| Hoisting speed | m/min | 8 | 8 | 8 | |||

| Trolley speed | 20 | 20 | |||||

| Rotating speed | r/min | 0.9 | 0.9 | 0.9 | |||

| Gantry speed | m/min | 1~26.5 | 3~30 | 1~25 | |||

| Max.wheel load | KN | 200 | 450 | 430 | |||

| Power source | 380V/10kV;50Hz;3 Phase or on request | ||||||

SAFETY FEATURES

Automatic rectify deviation control

Weight overload protection device

Top quality polyurethane buffer

Phase protection

Lifting limit switch

| Main Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Load capacity: | 30t-45t | (we can supply 30 ton to 45 ton,more other capacity you can learn from other project) | |||||

| Span: | 24m | (Standard we could supply span 24m, please contac our sales manager for more details) | |||||

| Lift height: | 15m-18.5m | (We can supply 15 m to 18.5 m,also we can design as your request ) | |||||

HYCrane VS Others

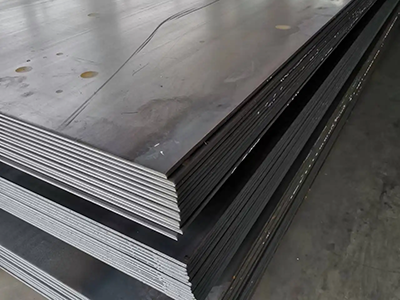

Our Material

1. The raw material procurement process is strict and

has been inspected by quality inspectors.

2. The materials used are all steel products from

major steel mills, and the quality is

guaranteed.

3. Strictly code into inventory.

1. Cut corners, originally used 8mm steel

plate,but used 6mm for customers.

2. As shown in the picture, old equipment is often

used for refurbishment.

3. Procurement of non-standard steel from small

manufacturers, product quality is unstable.

Other Brands

Our Material

1. Motor reducer and brake are three-in-one

structure

2. Low noise, stable operation and low maintenance

cost.

3. The built-in anti-drop chain can prevent

the bolts from being loosened, and avoid the

harm to the human body caused by the accidental fall

of the motor.

1.Old-style motors: It is noisy, easy to wear, short

service life, and high maintenance cost.

2. The price is low and the quality is very poor.

Other Brands

Our Wheels

All wheels are heat-treated and modulated, and the surface is coated with anti-rust oil to increase the aesthetics.

1. Do not use splash fire modulation, easy to

rust.

2. Poor bearing capacity and short service life.

3. Low price.

Other Brands

Our Controller

1. Our

inverters only make the crane run more stable

and safe, but also the fault alarm function of the

inverter makes the maintenance of the crane easier

and more intelligent.

2. The self-adjusting function of inverter

allows motor to self-adjust its power output

according to the load of the hoisted object at any

time, thereby saving the factory costs.

The control method of the ordinary contactor allows the crane to reach the maximum power after it is started, which not only causes the whole structure of the crane to shake to a certain degree at the moment of starting, but also slowly loses the service life of the motor.

Other Brands

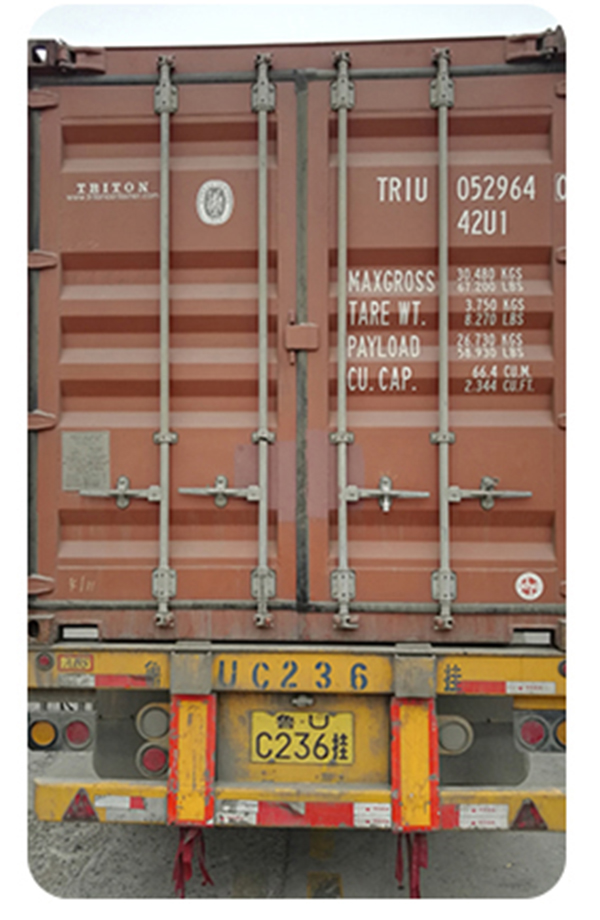

Transport

PACKING AND DELIVERY TIME

We have a complete production security system and experienced workers to ensure timely or early delivery.

RESEARCH ANDDEVELOPMENT

Professional power.

BRAND

Strength ofthe factory.

PRODUCTION

Years ofexperience.

CUSTOM

Spot isenough.

Asia

10-15days

Middle East

15-25days

Africa

30-40days

Europe

30-40days

America

30-35days

By National Station exporting standard plywood box,wooden palletor in 20ft & 40ft Container.Or as per your demands.