Products

MG type 5-50t double beam hook gantry crane

Description

MG gantry crane for subway construction is a special gantry crane which is developed on the basis of general gantry craneaccording to the operating requirements and working conditions of underground construction.The crane consists of crab, gantry, trolley travelling mechanism, hydraulic turnover mechanism, cab and electric equjpmentOn the crab is furnished a hydraulic turnover mechanism, which is composed of a hydraulic work station and a slag-turning hook

At the middle of the carrier-beam is a hook, which is used to lift common articles.

The trolley traveling mechanism is 4-wheel drive in 8 wheels. The motor fixed on the trolley drives wheels by vertical speedreducer A windoroof rail clamp is eguoped. t is detached from the ral when the crane is in normal operation. and when the cranestops working, the operator will put down the clamp to catch the rail so as to avoid the crane sliding.

The earth dumnping direction depends on the construction site

Technical Parameters

| Item | Unit | Result |

| Lifting capacity | ton | 5-50 |

| Lifting height | m | 10 11 |

| Span | m | 18-35m |

| Working environment temperture | °C | -20~40 |

| trolley travelling speed | m/min | 38-45 |

| lifting speed | m/min | 7-17 |

| hoist travelling speed | m/min | 34-47 |

| working system | A5 | |

| power source | three-phase 380V 50HZ |

MG Double-beam truss gantry crane is comprised of gantry, crane crab, trolley travelling mechanism, cab and electric control system.

The gantry, of a truss structure and having advantages of light structure, strong wind resistance and so on, is composed ofgirder, upper end girder,leg,lower end girder, traveling troley and platform railing. The girder is of a triangular truss structure,onwhich laid rails for crane crab to transversely move along the girder. The legs, of a truss structure, are weld by section steel. Theplatform, which is used to place electric equipment and used for repair, is furnished with protection railing outside.The closed cab is emploved for operation, where there are adjustable seat, insulating mat on the floor, toughened glass forthe window.fire extinouisher.lectric fan and auxliary egupment such as air conditoner. acoustc alarm and interphone which canbe furnished as required by users.

Technical Parameters

| Item | Unit | Result |

| Lifting capacity | ton | 5-50 |

| Lifting height | m | 10 11 |

| Span | m | 18-35m |

| Working environment temperture | °C | -20~40 |

| trolley travelling speed | m/min | 38.3-44.6 |

| lifting speed | m/min | 9-12 |

| handcard travelling speed | m/min | 34-47 |

| working system | A5 | |

| power source | three-phase 380V 50HZ |

Transport

PACKING AND DELIVERY TIME

We have a complete production security system and experienced workers to ensure timely or early delivery.

RESEARCH ANDDEVELOPMENT

Professional power.

BRAND

Strength ofthe factory.

PRODUCTION

Years ofexperience.

CUSTOM

Spot isenough.

Asia

10-15days

Middle East

15-25days

Africa

30-40days

Europe

30-40days

America

30-35days

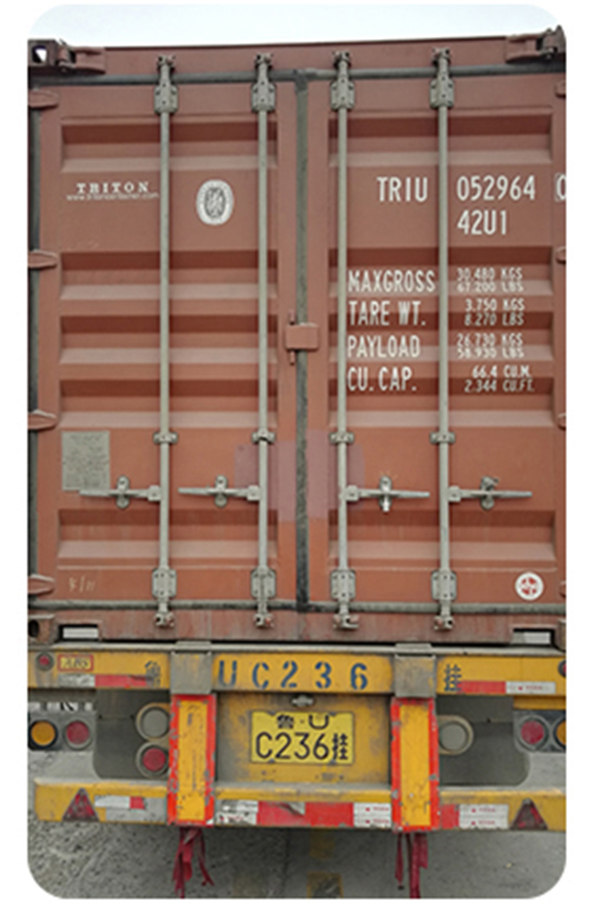

By National Station exporting standard plywood box,wooden palletor in 20ft & 40ft Container.Or as per your demands.