Products

Manufacture superior performance semi gantry crane for depot

Description

Designed with the highest precision and superior engineering, semi

gantry crane delivers unrivaled performance, reliability

and versatility. With its unique half-gantry construction,

semi-gantry crane will change the way businesses perform material

handling tasks, maximizing productivity and efficiency like never

before. Whether you operate in a manufacturing plant, construction

site or warehouse, semi-gantry cranes can enhance your lifting

capabilities.

The semi-gantry crane has a solid design and excellent load

capacity, achieving a seamless combination of mobility and

stability. Its unique design has the advantage of single-leg

installation, optimizing space utilization while ensuring a safe and

reliable lifting process. Made of high-quality materials for

increased durability, this crane can withstand even the most

demanding tasks. The semi-gantry cranes are equipped with advanced

safety features such as overload protection and emergency stop

system to ensure maximum safety of operators and workplaces.

In addition, this semi-gantry crane is able to operate in both

indoor and outdoor environments, so it is highly adaptable to

various environments. Its compact size facilitates easy handling and

easy repositioning without space constraints. Additionally, thanks

to its flexible span options, the crane enables efficient load

positioning for precise material placement. Semi-gantry cranes offer

unmatched performance and versatility, making them an indispensable

asset for any business looking to optimize their lifting

processes.

At HYCrane, we understand that every business has unique

lifting requirements. With this in mind, semi-gantry cranes can be

customized to meet specific needs and project specifications,

ensuring a bespoke solution exceeds client expectations. Our team of

highly skilled professionals is dedicated to providing comprehensive

customer support, from initial consultation to installation and

after-sales assistance. Additionally, our commitment to quality

ensures that semi-gantry cranes are rigorously tested and complied

with international industry standards, guaranteeing their

reliability and longevity.

2ton to 10ton

10m to 20m

A5

-20℃ to 40℃

Technical Parameters

| Semi Gantry Crane Main Specification | ||

|---|---|---|

| Item | Unit | Result |

| Lifting capacity | ton | 2-10 |

| Lifting height | m | 6 9 |

| Span | m | 10-20 |

| Working environment temperature | °C | -20~40 |

| Travelling speed | m/min | 20-40 |

| lifting speed | m/min | 8 0.8/8 7 0.7/7 |

| travelling speed | m/min | 20 |

| working system | A5 | |

| power source | three-phase 380V 50HZ | |

Product Details

01

Main girder

——

Steel plant material Q235B/Q345B with seamless once forming. CNC Cutting for complete steel plant.

02

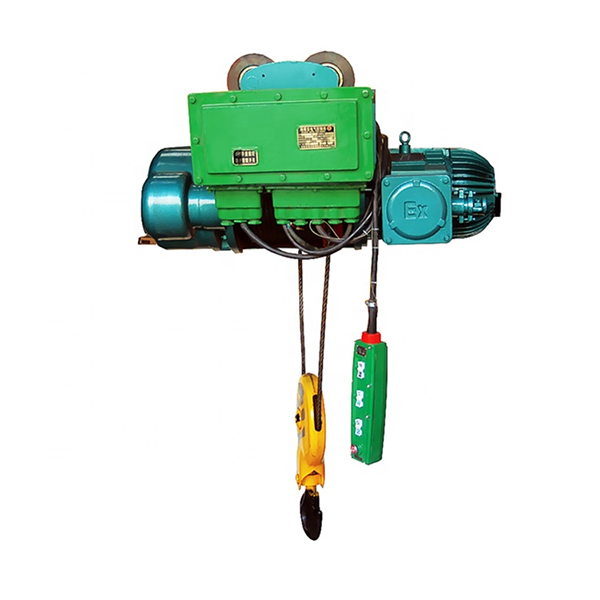

Hoist

——

Protection class F.Single/Double speed,trolley,reducer,drum,motor ,overload limiter switch

03

Outrigger

——

The legs are welded with high strength steel, and the rollers are installed below for easy movement.

04

Wheels

——

The wheels of crane crab, main beam and end carriage .

05

Hook

——

Drop Forged Hook, Plain ‘C’ type, Swiveling on Thrust Bearing, equipped with belt buckle.

06

Wireless Remote Control

——

Model: F21 F23 F24 Speed: Single speed, double speed. VFD control. Life of 500000 times.

Fine Workmanship

Low

Noise

Fine

Workmanship

Spot

Wholesale

Excellent

Material

Quality

Assurance

After-Sale

Service

01

Raw Material

——

GB/T700 Q235B and Q355B

Carbon Strctural Steel, best quality steel plate from

China Top-Class mills with Diestamps inlude heat

treatment number and bathch number, it can be tracked.

02

Welding

——

American welding Society, all important welds are carried out in accordance with welding procedures strictly.After welding, a certain amount of NDT control is carried out.

03

Welding Joint

——

The appearance is uniform.The joints between the weld passes are smooth.All off the welding slags and splashes are cleared out. There are no faults such as cracks,pores,bruises etc.

04

Painting

——

Before painting metal surfaces are shot peening sa required, two coats of pimer before assembly,two coats of synthetic enamel after testing. Painting adhesion is accorded to the class I of GB/T 9286.

Transport

PACKING AND DELIVERY TIME

We have a complete production security system and experienced workers to ensure timely or early delivery.

RESEARCH ANDDEVELOPMENT

Professional power.

BRAND

Strength ofthe factory.

PRODUCTION

Years ofexperience.

CUSTOM

Spot isenough.

Asia

10-15days

Middle East

15-25days

Africa

30-40days

Europe

30-40days

America

30-35days

By National Station exporting standard plywood box,wooden palletor in 20ft & 40ft Container.Or as per your demands.