Products

Introduction to the Types of Overhead Cranes

description

Knowing the difference between overhead cranes can do several things for your business. Overhead cranes can greatly improve production and efficiency in your work space. Choosing the right overhead crane can make work much easier. Choosing the wrong one, not so much. The different types of overhead cranes include gantry cranes, jib cranes, bridge cranes, workstation cranes, monorail cranes, top-running, and under-running. By reading the following article, you will get a brief, informative overview of all of the different types of overhead cranes. You’ll know enough by the end of this article to decide what type of overhead crane would best suit your needs and who you need to get in touch with to get your overhead crane.

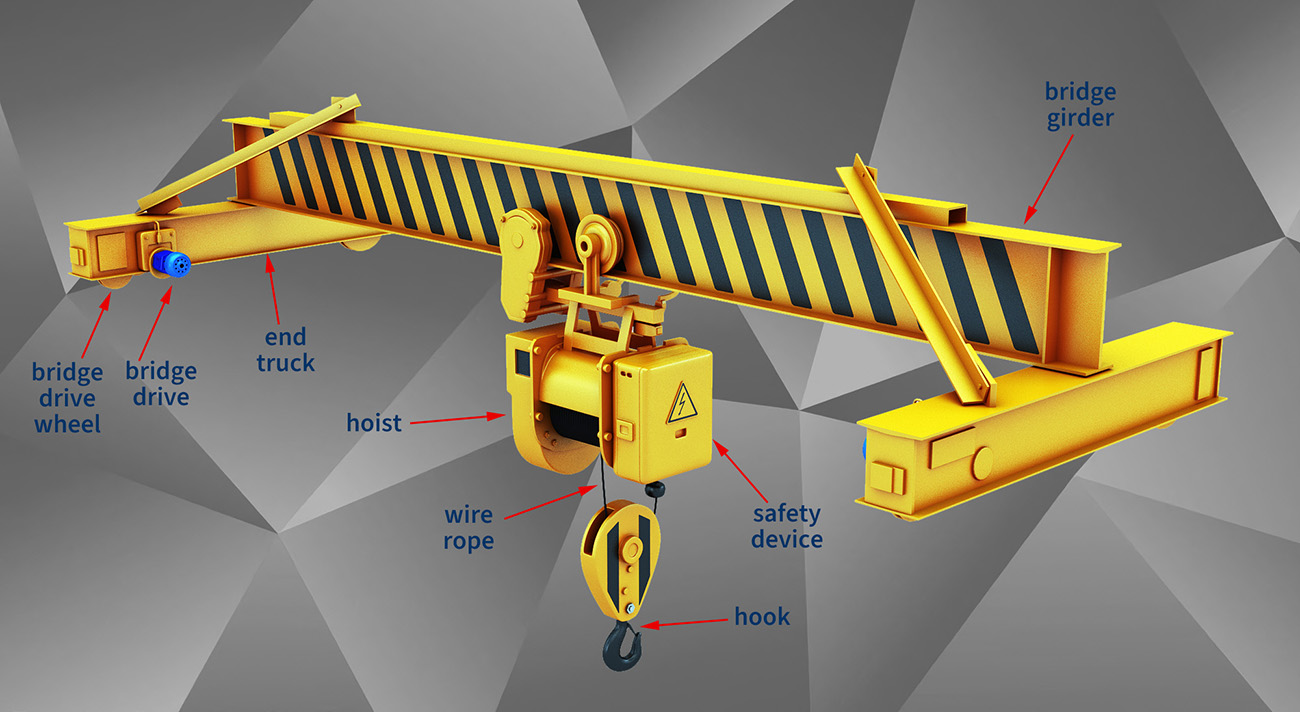

Bridge cranes are what you would most likely think of when thinking of an overhead crane. This type of overhead crane is built inside of a building and will normally use the structure of the building as it’s support. An overhead bridge crane almost always has a hoist which will move left or right. A lot of times these cranes will also run on a track, so the whole system can move forward or backwards through the building. Bridge cranes come in two common variations; single girder and double girder. Bridge girders are the beams that span across each runway.

The single girder bridge crane has one I-Beam or “girder” which supports the load. These cranes are typically lighter, and lift less weight than their double girder counterparts. They can still lift quite a bit compared to some other cranes, but their load capacity usually caps out around 15 tons.

Many industries use bridge cranes from automotive factories to paper mills. If you need to move something very heavy inside of a building, you can’t beat a bridge crane. They are highly reliable and make work inside buildings much more efficient.

The single girder bridge cranes are the less expensive of these two cranes, but also don’t have as much lifting power. So if you need to lift very heavy things, you may have to spend the extra money to get a double girder bridge crane.

technical parameters

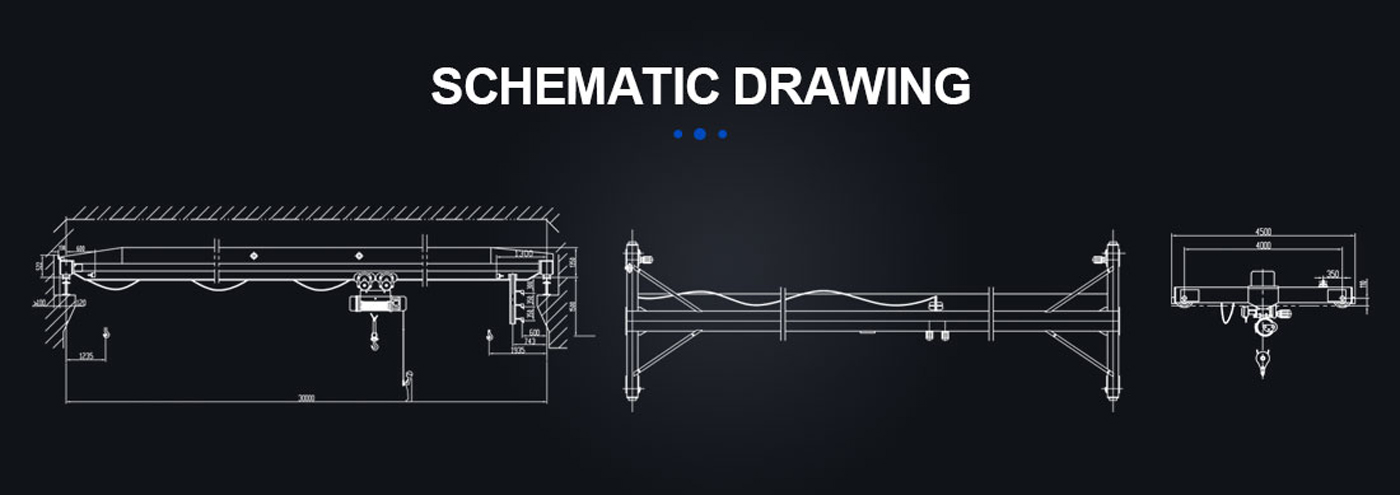

| parameters of single girder overhead crane | |||||||

|---|---|---|---|---|---|---|---|

| item | unit | result | |||||

| lifting capacity | ton | 1-30 | |||||

| working grade | A3-A5 | ||||||

| span | m | 7.5-31.5m | |||||

| Working environment temperature | °C | -25~40 | |||||

| working speed | m/min | 20-75 | |||||

| lifting speed | m/min | 8/0.8(7/0.7) 3.5(3.5/0.35) 8(7) | |||||

| lifting height | m | 6 9 12 18 24 30 | |||||

| travelling speed | m/min | 20 30 | |||||

| power source | three-phase 380V 50HZ | ||||||

product details

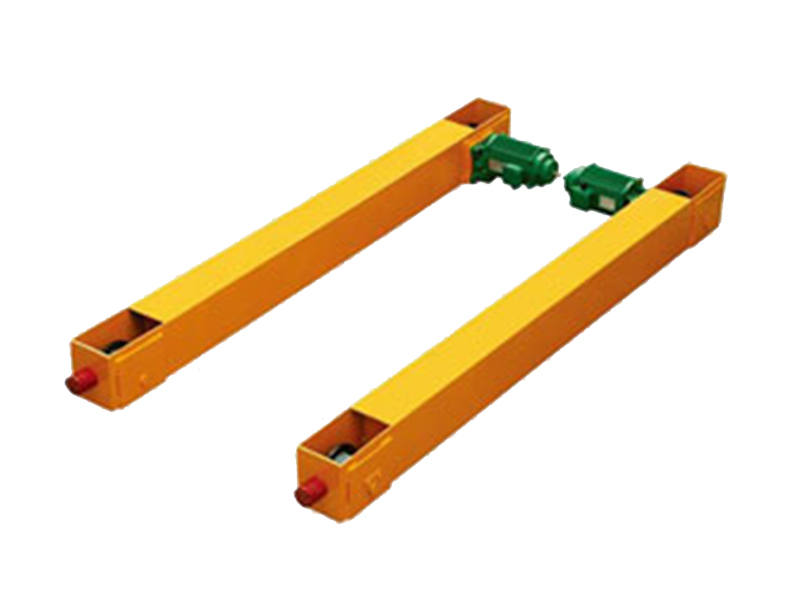

End Beam

T1.Uses rectangular tube manufacturing module 2.Buffer motor drive 3.With roller bearings and permanent iubncation

Main Beam

1.With strong box type and standard camber 2. There will have reinforcement plate inside themain girder

Crane Hoist

1.Pendent & remote control 2.Capacity:3.2-32t 3.Height: max 100m

Crane Hook

1.Pulley Diameter:125/0160/0209/0304 2.Material:Hook 35CrMo 3.Tonnage:3.2-32t

Fine Workmanship

Low

Noise

Fine

Workmanship

Spot

Wholesale

Excellent

Material

Quality

Assurance

After-Sale

Service

Application

IT IS USED IN MANY FIELDS

Satisfy the users' choice under different condition.

Usage: used in factories, warehouse, material stocks to lift goods,

to meet the daily lifting work.

Production Workshop

Warehouse

Store Workshop

Plastic Mold Workshop

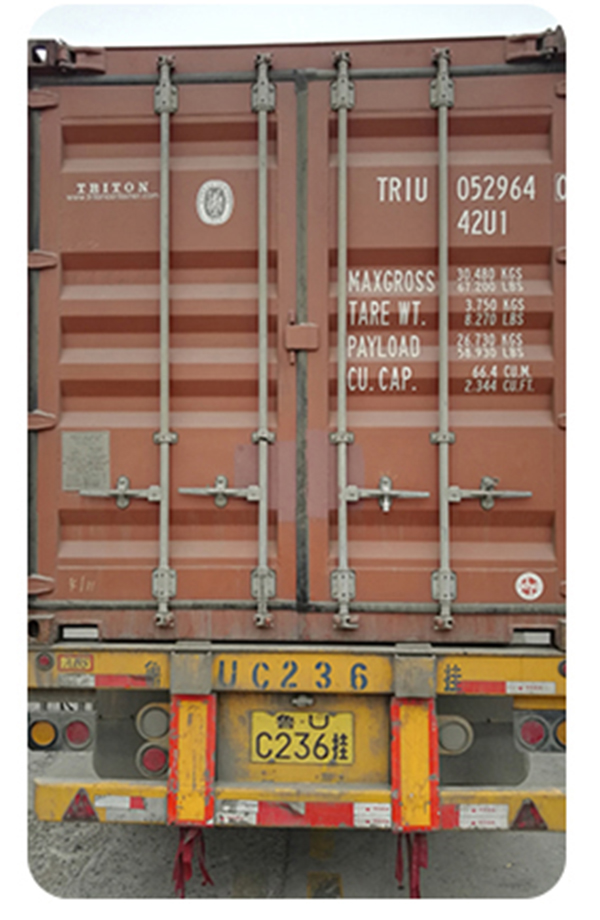

transport

- packing and delivery time

- we have a complete production security system and experienced workers to ensure timely or early delivery.

-

research and development

- professional power

-

brand

- strength of the factory.

-

production

- years of experience.

-

custom

- spot is enough.

-

asia

- 10-15days

-

middle east

- 15-25days

-

africa

- 30-40days

-

europe

- 30-40days

-

america

- 30-35days

By national station exporting standard plywood box,wooden palletor in 20ft & 40ft container. Or as per your demands.