Products

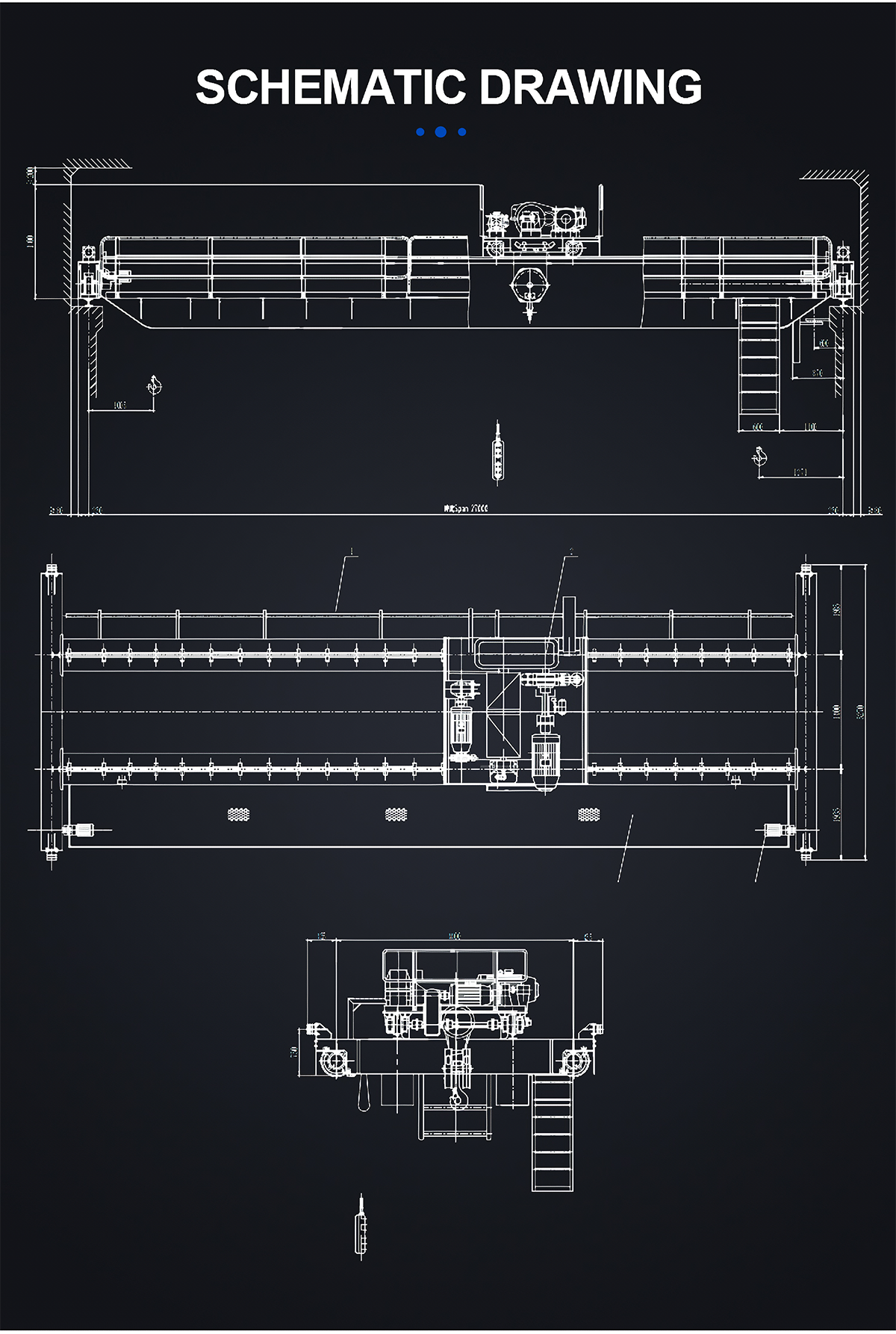

Heavy load capacity double girder overhead crane for workshop

Description

Double girder overhead crane is the ultimate solution for

heavy lifting and precise material handling. This state-of-the-art

equipment is

designed to deliver superior performance and increase productivity in a

variety of industrial applications. With its top-of-the-line operating

configuration and advanced features, this double girder overhead

traveling crane offers unrivaled efficiency, safety and reliability,

making it the first choice of many businesses.

The main advantages of the double-girder bridge erecting machine are its

robust construction and impressive load-carrying capacity. By utilizing

two strong beams running parallel to each other, the crane can lift

heavy loads effortlessly and has excellent stability. This design not

only ensures safety during operation, but also improves accuracy and

precision when handling materials. Whether in a manufacturing plant,

warehouse or construction site, this twin-girder crane can handle the

toughest lifting tasks with ease.

Another key advantage of double girder overhead traveling cranes is

their top-running configuration. By running along the top of the support

structure, it maximizes the available space in the facility and enables

efficient use of the work area below. This design allows the crane to

move flexibly, optimizing work flow and reducing any potential obstacles

that could hinder the lifting process. With its smooth operation and

seamless maneuverability, this crane helps simplify operations and

increase productivity, ultimately saving your business significant

costs.

In addition, the double girder overhead traveling crane has a series of

advanced features to ensure reliable and safe operation. The crane is

equipped with a modern control system including a variable frequency

drive and a radio remote control, enabling precise and responsive

movements for efficient loading and unloading. It also integrates safety

features such as overload protection, emergency stop buttons and limit

switches, guaranteeing the highest level of operator and workplace

safety.

The usage of double girder overhead crane

Generally speaking, double girder overhead travelling

crane can be applied to lifting, transporting,

loading and unloading materials in the fixed crotch

of the workshop in the station, harbor, industrial

and mining enterprises and other departments.

And its configuration hook can be used in machining,

assembly workshop, metal structure workshop,

metallurgy and casting workshop, and all kinds of

warehouse lifting work. And its configuration of

grappling hook is suitable for metallurgy, cement,

chemical industry and other industrial sectors or

open-air fixed span, engaged in the handling of bulk

materials.

The main parameters

| Capacity | 5ton to 320ton |

| Span | 10.5m to 31.5m |

| Working Grade | A7 |

| Warehouse Temperature | -25℃ to 40℃ |

Fine Workmanship

Spot Wholesale

Excellent Material

Quality Assurance

After-sale Service

We take great pride in the quality and workmanship of

our cranes as they are carefully designed and built to

meet the highest standards in the industry. With a focus

on durability, efficiency and safety, our lifting

equipment is the perfect solution for all your heavy

lifting needs.

What sets our lifting equipment apart is our attention

to detail and commitment to excellence. Every component

of our cranes undergoes rigorous testing and quality

control measures to ensure optimum performance and

longevity. From precision crafted gantry systems to

robust frames and advanced control mechanisms, every

aspect of our lifting equipment is engineered with

precision and expertise.

Whether you need a crane for a construction site,

manufacturing plant or any other heavy-duty job, our

lifting equipment is the epitome of reliability and

efficiency. With their craftsmanship and superior

engineering, our cranes deliver exceptional lifting

capabilities, allowing you to move any load with ease

and confidence. Invest in our reliable and durable

lifting equipment today and experience the power and

precision our products bring to your operation.

Technical Parameters

| Item | Unit | Result |

| Lifting capacity | ton | 5-320 |

| Lifting height | m | 3-30 |

| Span | m | 18-35 |

| Working environment temperature | °C | -20~40 |

| Lifting Speed | m/min | 5-17 |

| Trolley Speed | m/min | 34-44.6 |

| Working system | A5 | |

| Power source | three-Phase A C 50HZ 380V |

Application

IT

IS

USED

IN

MANY

FIELDS

Can

satisfy

the

users'

choice

under

different

condition.

Usage:

used

in

factories,

warehouse,

material

stocks

to

lift

goods,

to

meet

the

daily

lifting

work.

Transport

PACKING AND DELIVERY TIME

We have a complete production security system and experienced workers to ensure timely or early delivery.

RESEARCH ANDDEVELOPMENT

Professional power.

BRAND

Strength ofthe factory.

PRODUCTION

Years ofexperience.

CUSTOM

Spot isenough.

Asia

10-15days

Middle East

15-25days

Africa

30-40days

Europe

30-40days

America

30-35days

By National Station exporting standard plywood box,wooden palletor in 20ft & 40ft Container.Or as per your demands.