Products

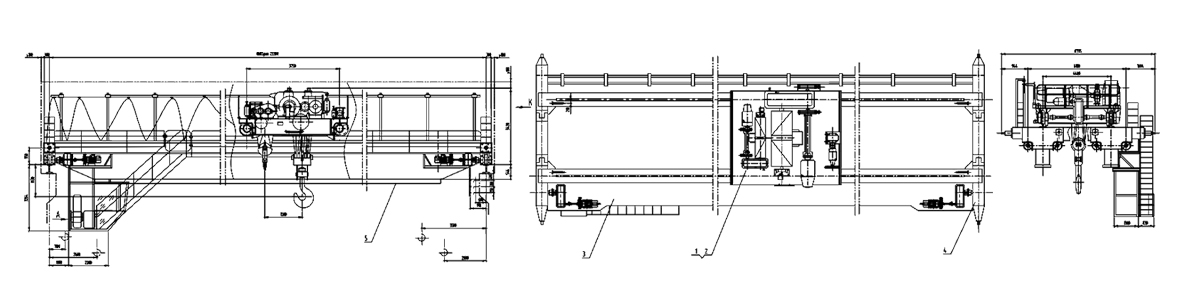

Foundry double girder overhead crane

Description

The foundry crane is designed to be operated efficiently, uninterruptedly and safely in continuous use.The design conforms to the requirements of international standards.

Because of a higher risk level, special safety features are designed for the foundry crane that transport molten metal. The main hoist mechanism includes four independent rope reevings, double service brakes on primary shafts, and backup brake acting on the rope drum. Rope equalizer beams are provided with a dampening unit to slow down equalizer beam tilting in case of wire rope failure. An upper emergency stop limit switch is also used in the main hoist. In addition to this overload protection, the ‘emergency stop’ system bypassed from PLC, derailment supports, main hoist over speed supervision, and end limit switches are automatically standard features of the equipment.

The foundry crane utilized for medium to heavy fabrication. These overhead cranes are ideally suited to casting factory.The Foundry crane is the main equipment for steel smelting production.

It is used to move steel or iron ladles in steel smelting workshop with high temperature and a lot of dust. Conventional scheme:using the closed cab.

Each organ is H class. And the insulating YZR type motor. working in the highest ambient temperature is 60°C,collocate with the advanced electric the winch is made with the welding's steel board ,the gear box with the detent and the ratchet wheel.

Power: AC 3Ph 380V 50Hz or according to client's requirement.

Control mode: Cabin control/remote control/control panel with pendant line

The capacity:5-320ton

The span : 10.5-31.5m

The working grade : A7

The working temperature:-25℃ to 40℃

Fine Workmanship

Low

Noise

Fine

Workmanship

Spot

Wholesale

Excellent

Material

Quality

Assurance

After-Sale

Service

MAIN BEAM

With strong box type and standard camber

There will have reinforcement plate inside themain girder

S

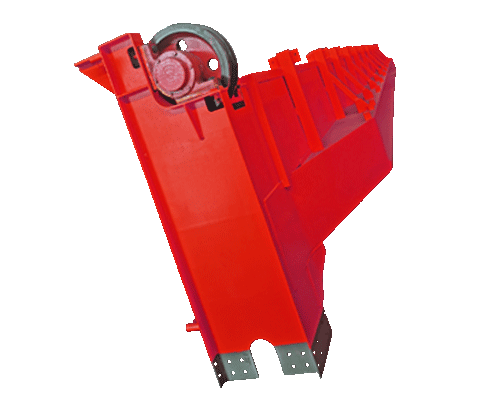

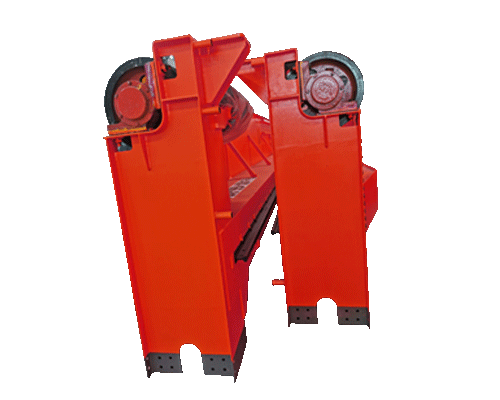

END BEAM

Uses rectangular tube manufacturing module

Buffer motor drive

With roller bearings and permanent iubncation

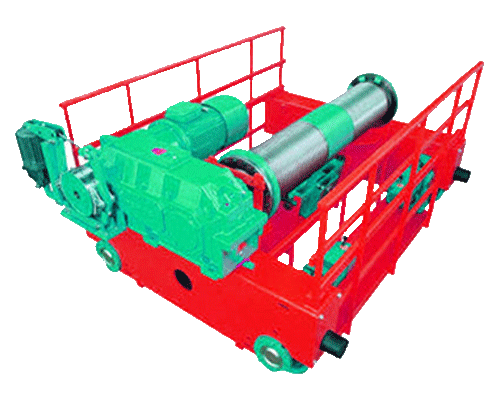

CRANE TROLLEY

1.High working duty hoist mechanism.

2.Working duty:A7-A8

3.Capacity:10-74t.

CRANE HOOK

Pulley Diameter:Ø125/Ø160/Ø209/Ø304

Material:Hook 35CrMo

Tonnage:10-74t

S

Application&Transport

IT IS USED IN MANY FIELDS

Satisfy the users' choice under different condition.

Usage: used in factories, warehouse, material stocks to lift goods, to meet the daily lifting work.

Metallurgy

Casting

Material room

PACKING AND DELIVERY TIME

We have a complete production security system and experienced workers to ensure timely or early delivery.

RESEARCH ANDDEVELOPMENT

Professional power.

BRAND

Strength ofthe factory.

PRODUCTION

Years ofexperience.

CUSTOM

Spot isenough.

Asia

10-15days

Middle East

15-25days

Africa

30-40days

Europe

30-40days

America

30-35days

By National Station exporting standard plywood box,wooden palletor in 20ft & 40ft Container.Or as per your demands.