Products

Efficient rail mounted container gantry crane with trolley

description

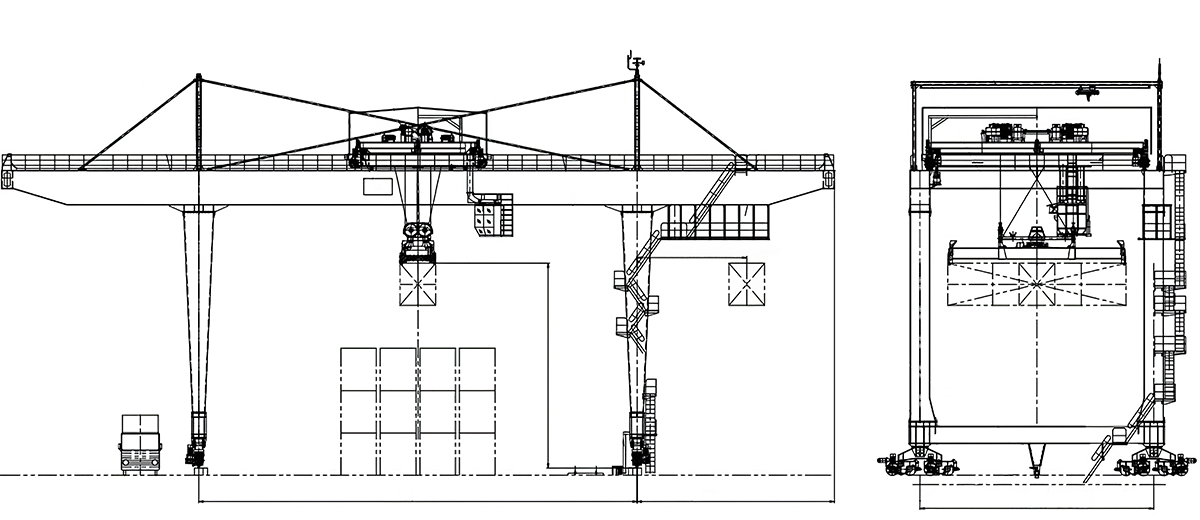

The rmg crane's rail mounted design allows for precise and smooth movement along a fixed path. This ensures efficient container handling operations within the port. Its sturdy structure is specifically designed to handle heavy loads, providing stability and safety during lifting and transportation. With its ability to lift containers to higher heights and span wider distances, the rmg crane is perfectly suited for large-scale container terminals.

Moreover, the rmg crane has played a pivotal role in modernizing ports and harbors. Its advanced technology and automation capabilities have optimized productivity and reduced labor costs in port operations. Through the use of sophisticated software and control systems, the rmg crane can precisely position containers and carry out smart handling operations. This has significantly improved the efficiency and reliability of port operations, resulting in faster vessel turnaround times and enhanced customer satisfaction.

The rail-mounted gantry crane (rmg crane) has revolutionized the port industry with its rail-mounted design and advanced technology. Its automation capabilities have significantly improved productivity and efficiency. Port operators can maximize efficiency by selecting the crane that best fits their requirements, considering factors such as size, mobility, and operational scale. The rmg crane offers excellent productivity and stability, providing a reliable solution for large-scale port operations.

technical parameters

parameters of container rail mounted gantry crane |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| item | unit | result | |||||||

| lifting capacity | ton | 30.5-320 | |||||||

| Lifting height | m | 15.4-18.2 | |||||||

| Span | m | 35 | |||||||

| Working environment temperature | °C | -20~40 | |||||||

| Hoisting Speed | m/min | 12-36 | |||||||

| Crane Speed | m/min | 45 | |||||||

| Trolley Speed | m/min | 60-70 | |||||||

| Working system | A6 | ||||||||

| Power source | three-Phase ac 50HZ 380V | ||||||||

product details

main beam

· with strong box type and standard camber

· there will have reinforcement plateinside the

main

girder

crane trolley

· high working duty hoist mechanism.

· working duty: a6-a8

· capacity:40.5t-70t.

container spreader

· reasonable structure, strong carryingcapacity, and can be processed and customized in 20ft to 45ft range expansion

cable drum

· the altitude does not exceed2000 meters.

· the protection class ofthe collector box is

ip54.

Fine Workmanship

Low

Noise

Fine

Workmanship

Spot

Wholesale

Excellent

Material

Quality

Assurance

After-Sale

Service

01

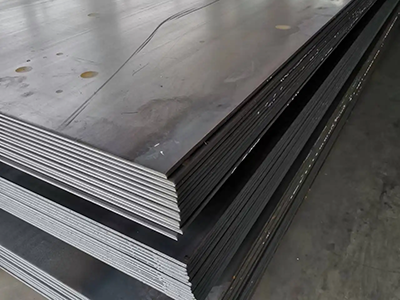

Raw Material

——

GB/T700 Q235B and Q355B

Carbon Strctural Steel, best quality steel plate from

China Top-Class mills with Diestamps inlude heat

treatment number and bathch number, it can be tracked.

02

Welding

——

American welding Society, all important welds are carried out in accordance with welding procedures strictly.After welding, a certain amount of NDT control is carried out.

03

Welding Joint

——

The appearance is uniform.The joints between the weld passes are smooth.All off the welding slags and splashes are cleared out. There are no faults such as cracks,pores,bruises etc.

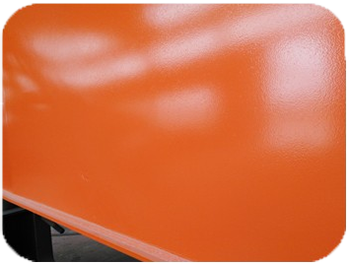

04

Painting

——

Before painting metal surfaces are shot peening sa required, two coats of pimer before assembly,two coats of synthetic enamel after testing. Painting adhesion is accorded to the class I of GB/T 9286.

HYCrane VS Others

Our Material

1. The raw material

procurement process is strict and

has been inspected by quality inspectors.

2. The materials used are all steel products from

major steel mills, and the quality is

guaranteed.

3. Strictly code into inventory.

1. Cut corners, originally used 8mm steel

plate,but used 6mm for customers.

2. As shown in the picture, old equipment is often

used for refurbishment.

3. Procurement of non-standard steel from small

manufacturers, product quality is unstable.

Other Brands

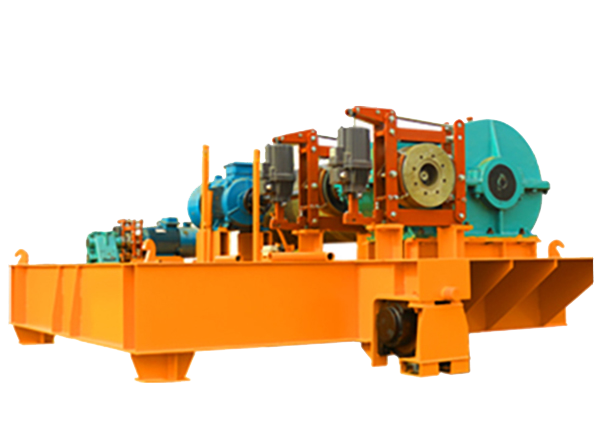

Our Motor

1. Motor reducer and brake

are three-in-one

structure

2. Low noise, stable operation and low maintenance

cost.

3. The built-in anti-drop chain can prevent

the bolts from being loosened, and avoid the

harm to the human body caused by the accidental fall

of the motor.

1.Old-style motors: It is noisy, easy to wear, short

service life, and high maintenance cost.

2. The price is low and the quality is very poor.

Other Brands

Our Wheels

All wheels are heat-treated and modulated, and the surface is coated with anti-rust oil to increase the aesthetics.

1. Do not use splash fire modulation, easy to

rust.

2. Poor bearing capacity and short service life.

3. Low price.

Other Brands

our controller

our inverters make the crane run more stable and safe, and make the maintenance of the more intelligent and easy.

the self-adjusting function of inverter allows motor to self-adjust its power output according to the load of the hoisted object at any time, thereby saving the factory costs.

the control method of the ordinary contactor allows the crane to reach the maximum power after it is started, which not only causes the whole structure of the crane to shake to a certain degree at the moment of starting, but also slowly loses the service life of the motor.

other brands

transport

- packing and delivery time

- we have a complete production security system and experienced workers to ensure timely or early delivery.

-

research and development

- professional power

-

brand

- strength of the factory.

-

production

- years of experience.

-

custom

- spot is enough.

-

asia

- 10-15days

-

middle east

- 15-25days

-

africa

- 30-40days

-

europe

- 30-40days

-

america

- 30-35days

By national station exporting standard plywood box,wooden palletor in 20ft & 40ft container. Or as per your demands.