Products

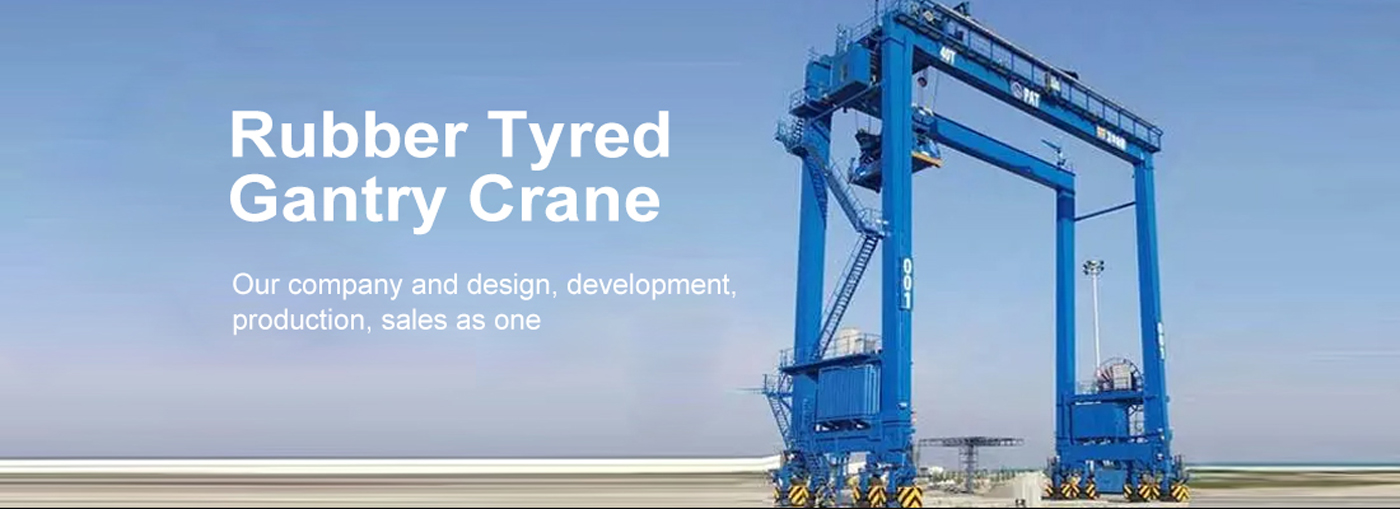

Easy operation container rubber-tyred gantry crane for port

Description

Designed for unrivaled efficiency and flexibility, Rubber-tyred

gantry crane offers a versatile and reliable solution for

lifting and moving heavy loads. With durable rubber tires, the crane

can operate indoors and outdoors with no need for additional

equipment and reduced downtime. Whether you're in construction,

manufacturing or logistics, rubber-tyred gantry cranes are the

perfect choice to streamline operations and maximize

productivity.

Rubber-tyred gantry cranes feature solid construction and advanced

technology designed to provide superior lifting capabilities. With a

lifting capacity of up to 350 ton, this crane can

handle even the heaviest loads with ease. Its precise controls

ensure smooth, accurate movement, allowing the operator to easily

navigate and maneuver in tight spaces. The crane is equipped with a

reliable braking system that ensures optimum safety during

operation, minimizes the risk of accidents and ensures the

well-being of employees.

In conclusion, rubber-tyred gantry cranes provide a comprehensive

and advanced solution for your material handling needs. Its sturdy

construction, exceptional lifting capacity and advanced automation

features make it perfect for industries ranging from construction to

logistics. With its mobility and versatility, the crane ensures

seamless indoor and outdoor operations without the need for

additional equipment. Investing in a rubber-tyred gantry crane can

increase your productivity, streamline your operations, and take

your business to new heights.

One of the main advantages of rubber-tyred gantry

cranes is their

mobility. The crane is equipped with specially

designed rubber tires

that provide excellent traction on a variety of

terrains. This

eliminates the need for costly and time-consuming

track or runway

installations, as the crane can effortlessly

navigate your facility.

Whether you need to transport heavy machinery,

containers or other

bulky materials, this crane offers unrivaled

flexibility to move

loads from one location to another.

Rubber-tyred gantry cranes also boast advanced

automation features

that further increase their efficiency and

productivity. With

programmable routines and remote control

capabilities, operators can

streamline operations by optimizing workflow and

reducing manual

labor. The crane's intelligent systems enable

precise positioning

and sequential task management, ensuring that every

operation is

performed seamlessly. Additionally, its

user-friendly interface and

real-time monitoring enable operators to monitor

performance data

and quickly identify any potential issues,

minimizing downtime and

maximizing uptime.

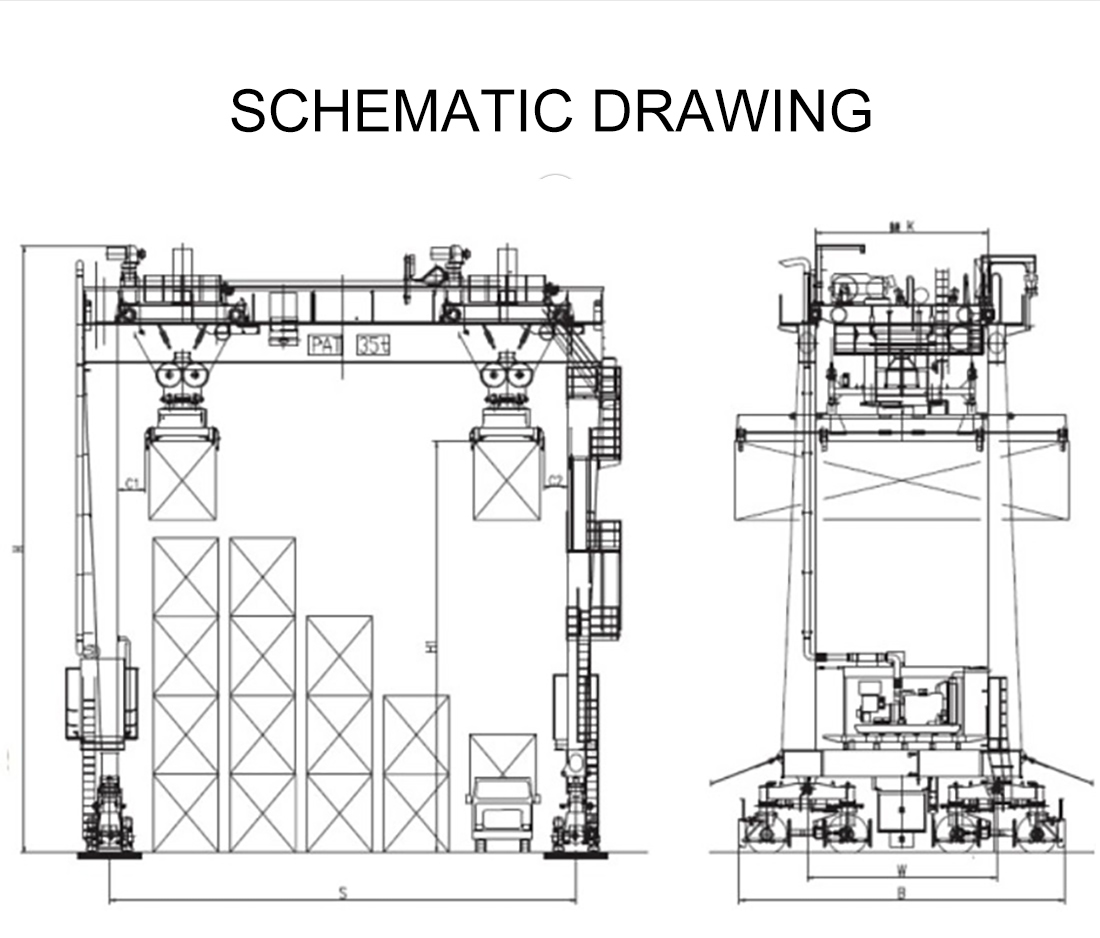

| Main Specification | ||

|---|---|---|

| The capacity | 30.5 to 350 | ton |

| The span | 18 to 50 | m |

| The working grade | A6 | - |

| The working temperature | -20 to 40 | ℃ |

Technical Parameters

| Parameters of Rubber Tyred Gantry Crane | ||

|---|---|---|

| Item | Unit | Result |

| Lifting capacity | ton | 30.5-350 |

| Lifting height | m | 15-18 |

| Span | m | 18-50 |

| Working environment temperture | °C | -20~40 |

| Hoisting speed | m/min | 12-36 |

| Trolley speed | m/min | 60-70 |

| Working system | A6 | |

| Power source | three-Phase A C 50HZ 380V | |

Product Details

01

Main Beam

——

1.with strong box type and standardcamber

2.There will have reinforcement plateinside the main

girder

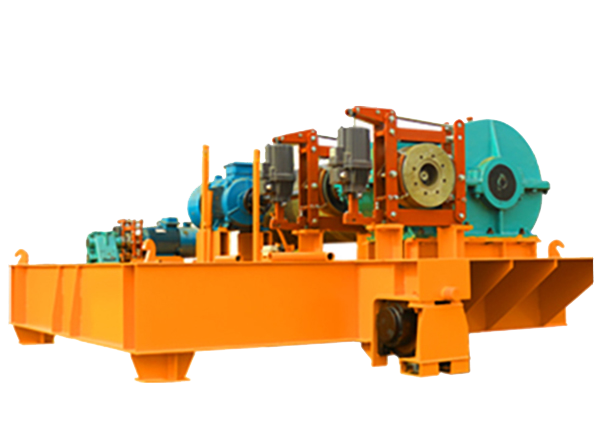

02

Crane Trolley

——

1.High working duty hoist mechanism.

2.Working duty:A6-A8

3.Capacity:40.5-70t.

03

Container Spreader

——

Reasonable structure, goodversatility, strong carryingcapacity, and can be processed and customized

04

Cable Drum

——

1.The altitude does not exceed2000 meters.

2.The protection class ofthe collector box is lP54.

05

Crane Cabin

——

1.Close and open type.

2.Air-conditioning provided.

3.Interlocked circuit breakerprovided.

06

Crane Travelling Machine

——

1.Material: ZG55, ZG65, ZG50SiMn oron request

2.wheel diameter: 250mm-800mm.

Fine Workmanship

Low

Noise

Fine

Workmanship

Spot

Wholesale

Excellent

Material

Quality

Assurance

After-Sale

Service

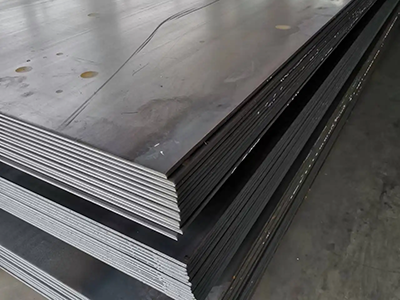

HYCrane VS Others

Other brand:

1. The raw

material

procurement

process is

strict and

has

been

inspected

by quality

inspectors.

2. The

materials

used are all

steel

products

from major

steel mills,

and

the quality

is

guaranteed.

3. Strictly

code

into

inventory.

Other brand:

1. Cut

corners,

such as:

originally

used

8mm steel

plate,

but used 6mm

for

customers.

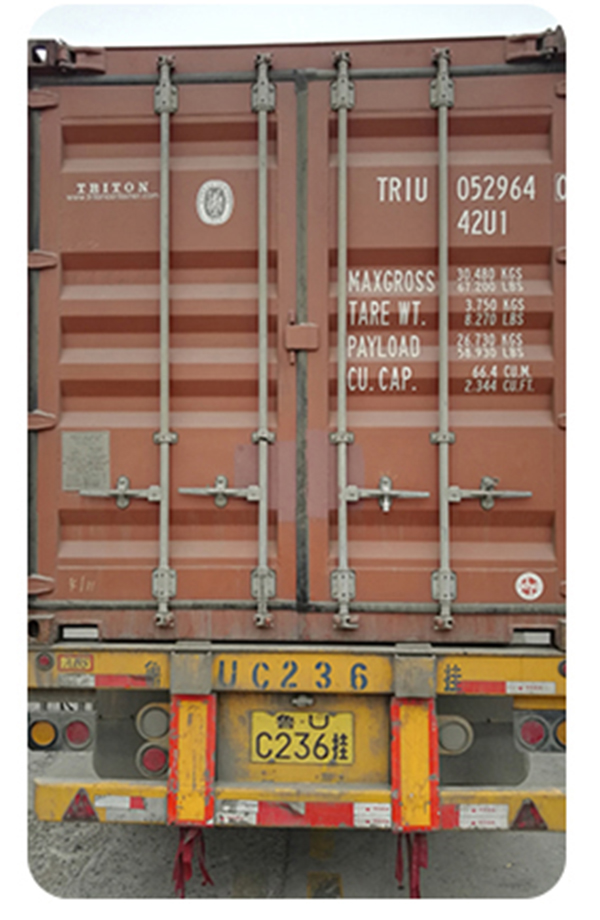

2. As shown

in

the picture,

old

equipment is

often used

for

refurbishment.

3.

Procurement

of

non-standard

steel from

small

manufacturers,

product

quality

is unstable,

and

safety

risks are

high.

Our brand:

1. Motor

reducer

and brake

are

three-in-one

structure

2. Low

noise,

stable

operation

and low

maintenance

cost.

3. The

motor's

built-in

anti-drop

chain

can prevent

the

motor's

bolts

from being

loosened,

and

avoid the

harm

to

the human

body

caused by

the

accidental

fall

of the

motor, which

increases

the

safety of

the

equipment.

Other brand:

1.Old-style

motors: It

is

noisy, easy

to

wear, short

service

life,

and high

maintenance

cost.

2. The price

is

low and the

quality is

very

poor.

Our brand:

All wheels are heat-treated and modulated, and the surface is coated with anti-rust oil to increase the aesthetics.

Other brand:

1. Do not use

splash fire

modulation,

easy

to rust.

2. Poor

bearing

capacity and

short

service

life.

3. Low

price.

Our brand:

1. Adopting

Japanese

Yaskawa

or German

Schneider

inverters

not

only make

the

crane run

more

stable and

safe, but

also

the fault

alarm

function of

the

inverter

makes the

maintenance

of

the crane

easier

and more

intelligent.

2. The

self-adjusting

function of

the

inverter

allows

the motor to

self-adjust

its

power output

according to

the load of

the

hoisted

object

at any time,

which not

only

increases

the service

life

of the

motor,

but also

saves the

power

consumption

of

the

equipment,

thereby

saving the

factory Cost

of

electricity.

Other brand:

1.The control method of the ordinary contactor allows the crane to reach the maximum power after it is started, which not only causes the whole structure of the crane to shake to a certain degree at the moment of starting, but also slowly loses the service life of the motor.

Transport

PACKING AND DELIVERY TIME

We have a complete production security system and experienced workers to ensure timely or early delivery.

RESEARCH ANDDEVELOPMENT

Professional power.

BRAND

Strength ofthe factory.

PRODUCTION

Years ofexperience.

CUSTOM

Spot isenough.

Asia

10-15days

Middle East

15-25days

Africa

30-40days

Europe

30-40days

America

30-35days

By National Station exporting standard plywood box,wooden palletor in 20ft & 40ft Container.Or as per your demands.