Products

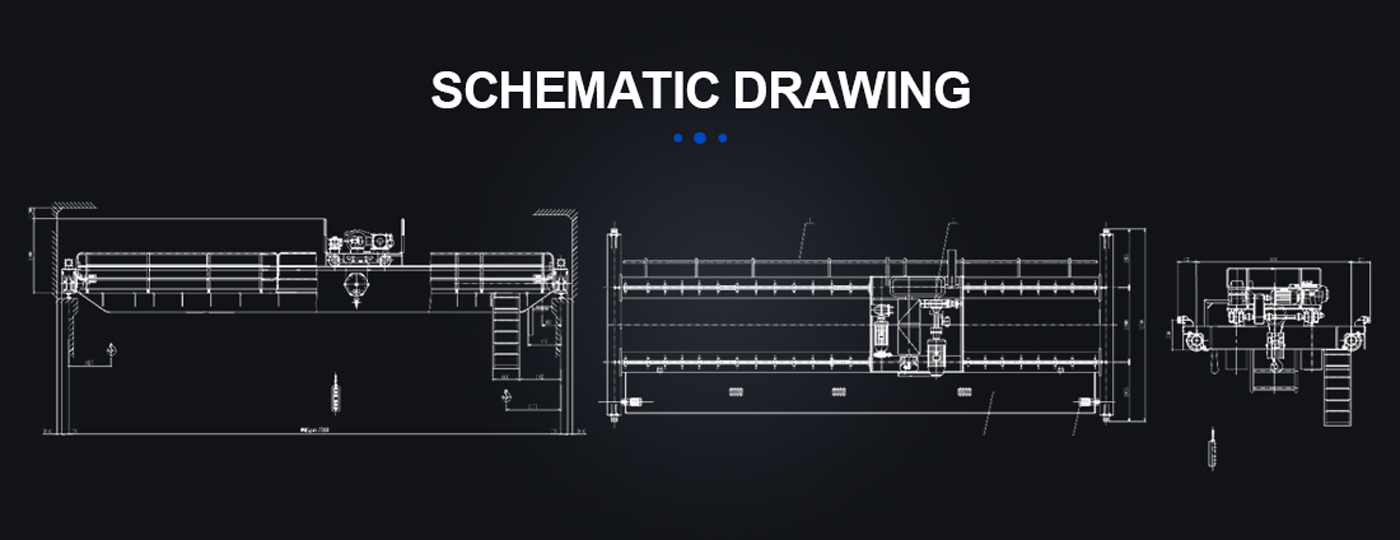

Double Girder Overhead Bridge Crane

Description

Double girder overhead crane mainly consists of bridge, trolley travelling mechanism, crab and electrical appliances, and is divided into 2 working grades of A5 and A6 according to the use frequency.

Double girder overhead crane can be used to lift loads from 5 tons to 350 tons, which is widely used to upload and move of normal weight in the fixed crossing space and also can work with various special-purpose hoist in special operations.

Double girder overhead crane is widely used to upload and move of normal weight in the fixed crossing space and also can work with various special-purpose hoist in special operations.

Double girder overhead crane utilized for medium to heavy fabrication. The top running configuration is best used in cases where the end user has issues with headroom. The most space efficient configuration is the double girder, top running crane system.

Control mode: Cabin control/remote control/control panel with pendant line

The capacity:5-350ton

The span : 10.5-31.5m

The working grade : A5-A6

The working temperature:-25℃ to 40℃

End beam

1.Uses rectangular tube manufacturing module

2.Buffer motor drive

3.With roller bearings and permanent iubncation

Main beam

1.With strong box type and standard camber

2.There will have reinforcement plate inside themain girder

Crane Trolley

1.High working duty hoist mechanism.

2.Working duty:A3-A8

3.Capacity:5-320t.

Crane Hook

1.Pulley Diameter:125/160/D209/0304

2.Material:Hook 35CrMo

3.Tonnage:3.2-32t

Technical Parameters

Technical Parameters

| Item | Unit | Result |

| Lifting capacity | ton | 5-350 |

| Lifting height | m | 1-20 |

| Span | m | 10.5-31.5 |

| Working environment temperature | °C | -25~40 |

| Hoisting Speed | m/min | 5.22-12.6 |

| trolley speed | m/min | 17.7-78 |

| Working system | A5-A6 | |

| Power source | three-Phase A C 50HZ 380V |

Application

IT IS USED IN MANY FIELDS

Can satisfy the users' choice under different condition.

Usage: used in factories, warehouse, material stocks to lift goods, to meet the daily lifting work.

Production Workshop

Warehouse

Store Workshop