Products

Customized Electric Single Beam Overhead Crane EOT Crane 15 Ton Price

Description

The new European hoist crane is designed and manufactured according to the FEM standards. Cranes are mainly made up by main beams, end beams, trolleys, electrical parts and control rooms and other components. The standard lifting capacity are 5~20 t. We also can customized the lifting capacity depend on customer requirements. Span is from 7.5 m to 31.5 m. The crane is used widely, it is not only extremely safe, good design, ergonomic, material handling convenient and efficient, but also save the warehouse space due to its compact size structure. Used for machinery manufacturing assembly, warehouse and other places, for the machine equipment manufacturing, maintenance, warehouses and other places, but not suitable for the self-explosion and fire to do dangerous, full corrosive gas medium and relative humidity greater than 85% of the work in the place, not suitable for hanging transport metal.

FOR CRANE SAFETY, WHAT WE DO?

Our single girder overhead crane apply measures as below to insure crane safety during operation: Overload limiter, for liftingsafety Electromagnetic brake, quick response, up to 1000000 times braking lifespan. Limit switch for long traveling Welding quality inspection, guarantee load capacity of main girder and end beam/carriage. Thermalelectromechanical protector Electrical protection system

Technical design base:

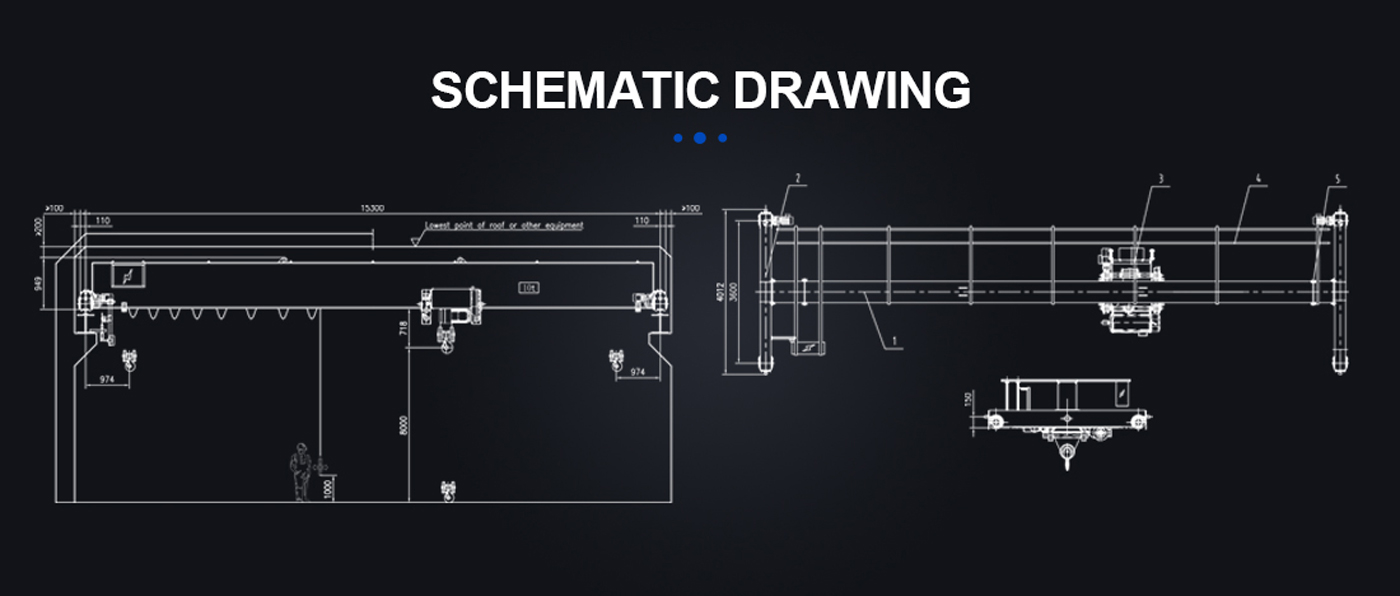

Capacity: According to weight of lifting load, working environment, plant structure load capacity, crane wheel pressure and so on. Our single girder overhead crane can be designed up to 20t capacity. Single girder underhung/suspension crane can be designed up to 20t capacity.

Span: According to distance between runways or columns in workshop, our engneers can derive specific technical scheme. Further more, if customer can provide layout of the plant, our engineer will offer precise and economic solution. Generally, span of crane can be up to 31.5m and available for customized span.

Lifting height: According to distance from roof top to ground in workshop, our engneers can confirm lifting height needed. Also, height from roof top to runway will be very important for installation. If customer can provide drawing of the plant section, we can find better choice for you.

Power supply: Power grid is very different from country to country. To insure our equipments have stable and

reliable performance, please inform us local power supply conditions. For example: Voltage 220v,380V, 400v, 415v or 440v. Frequency 50Hz/60Hz. 3 phase.

Control method: Pendant control, remote control(wireless radio control), cabin control.

End beam

1.Uses rectangular tube manufacturing module

2.Buffer motor drive

3.With roller bearings and permanent iubncation

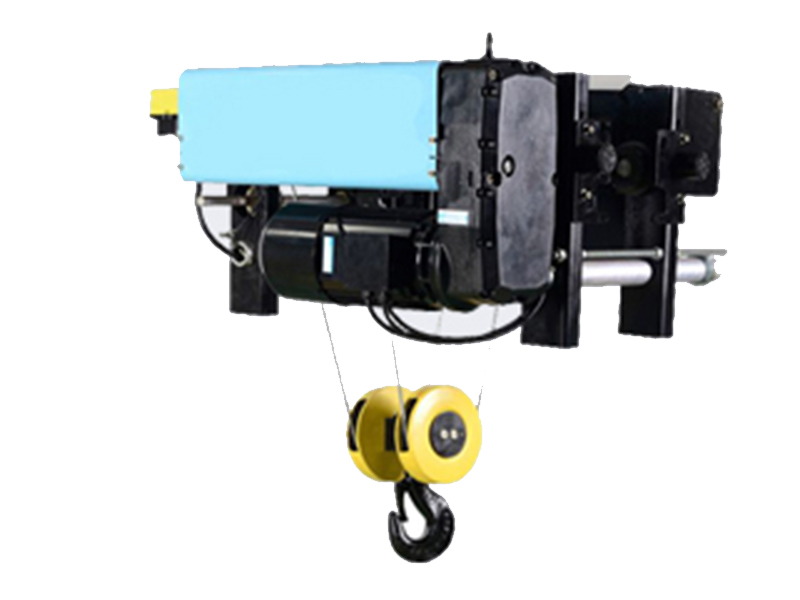

Europe Hoist

1.Pendent & remote control

2.Capacity:3.2-32t

3.Height: max 100m

Main beam

1.With strong box type and standard camber

2.There will have reinforcement plate inside themain girder

Crane Hook

1.Pulley Diameter:125/0160/D209/0304

2.Material:Hook 35CrMo

3.Tonnage:3.2-32t

Product Details

Technical Parameters

| Item | Unit | Result |

| Lifting capacity | ton | 0.25-20ton |

| Working grade | Class C or D | |

| Lifting Height | m | 6-30m |

| Span | m | 7.5-32m |

| Working environment temperature | °C | -25~40 |

| Control mode | cabin control/remote control | |

| power source | three-phase 380V 50HZ |

Application

IT IS USED IN MANY FIELDS

Can satisfy the users' choice under different condition.

Usage: used in factories, warehouse, material stocks to lift goods, to meet the daily lifting work.

Production Workshop

Warehouse

Store Workshop