Products

Customized design launching gantry crane for bridge construction

description

The launching girder gantry crane, a powerful and versatile lifting machine, has become an indispensable tool in the construction industry. Its primary purpose is to assist in the construction and installation of bridges, viaducts, and elevated highways. This crane plays a crucial role in safely lifting heavy structural components, such as precast concrete girders, and precisely placing them in their designated positions.

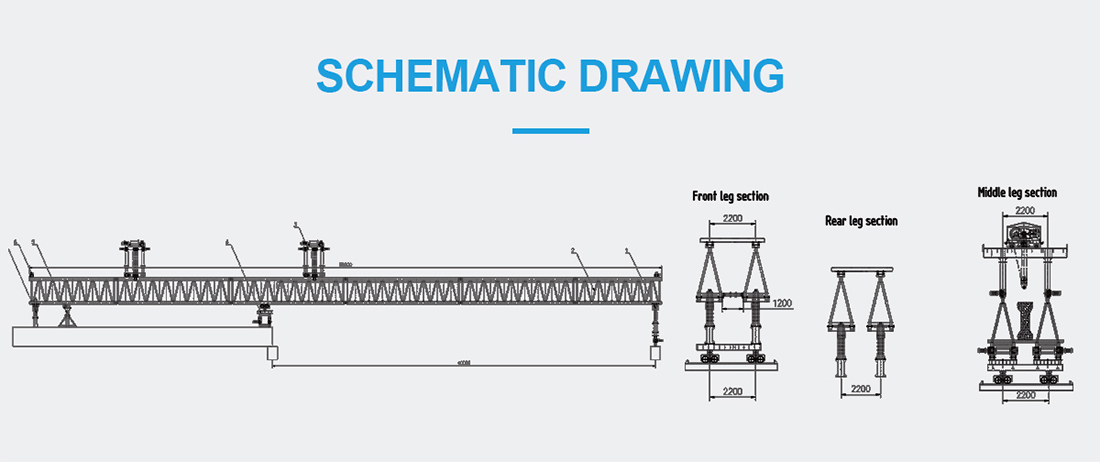

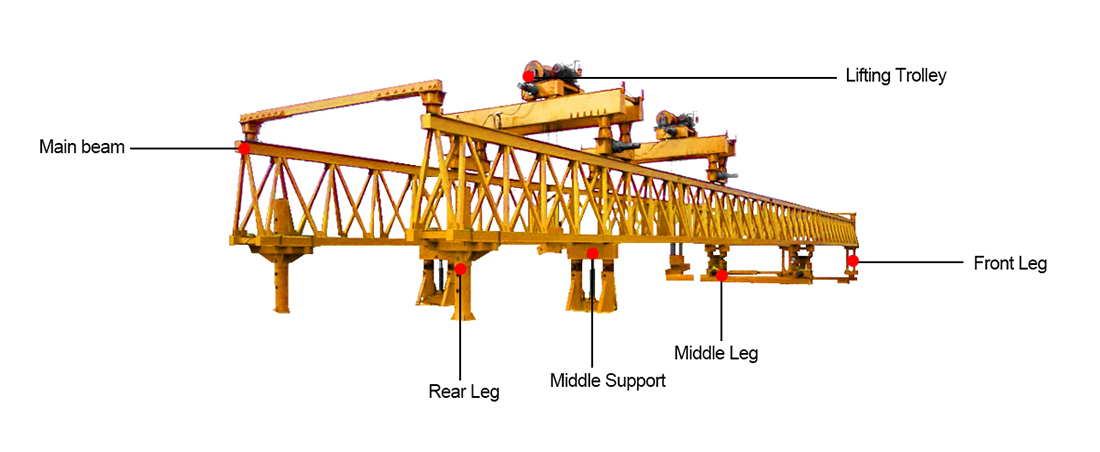

Now, let's delve into the structural characteristics that make the launching girder gantry crane a standout in the world of construction. At the core of this crane is a robust framework that provides stability and support during lifting operations. This framework is usually made of high-quality steel, ensuring maximum strength and durability. It consists of vertical columns, horizontal girders, and diagonal bracing, all meticulously engineered to withstand heavy loads and maintain stability under adverse conditions.

One of the notable features of the launching girder gantry crane is its adjustable tracks. These tracks, located on both sides of the crane, allow for easy movement along the construction site. With the ability to extend or retract, the crane can adapt to various bridge spans, ensuring optimal positioning during the lifting process. This adjustability is especially crucial when executing complex construction projects with varying geometries.

To support the lifting operation, the crane utilizes several lifting mechanisms. The main lifting mechanism is typically a hydraulic jack system, which provides the force needed to elevate the heavy precast elements. These jacks are strategically positioned along the main girder, allowing for uniform load distribution during lifting. In addition, the crane is equipped with auxiliary mechanisms such as outriggers and stabilizers, which enhance stability and minimize any swaying or tilting that could occur during the lifting process.

Safety is of paramount importance in any construction project, and the launching girder gantry crane is no exception. Thus, it is equipped with an array of safety features. These include limit switches, emergency stop buttons, and overload protection systems. These measures ensure that the crane operates within its specified capacity and prevents any potential accidents or damage due to overload. Moreover, the crane is designed with anti-tipping devices and wind speed sensors to handle adverse weather conditions, further ensuring the safety of both workers and the construction site.

technical parameters

| parameters of launching girder gantry crane | |||||||

|---|---|---|---|---|---|---|---|

| MCJH50/200 | MCJH40/160 | MCJH40/160 | MCJH35/100 | MCJH30/100 | |||

| lifting capacity | 200t | 160t | 120t | 100t | 100t | ||

| applicable span | ≤55m | ≤50m | ≤40m | ≤35m | ≤30m | ||

| applicable skew bridge angle | 0-450 | 0-450 | 0-450 | 0-450 | 0-450 | ||

| trolley lifting speed | 0.8m/min | 0.8m/min | 0.8m/min | 1.27m/min | 0.8m/min | ||

| rolley longitudinal moving speed | 4.25m/min | 4.25m/min | 4.25m/min | 4.25m/min | 4.25m/min | ||

| cart longitudinal moving speed | 4.25m/min | 4.25m/min | 4.25m/min | 4.25m/min | 4.25m/min | ||

| cart transverse moving speed | 2.45m/min | 2.45m/min | 2.45m/min | 2.45m/min | 2.45m/min | ||

| transportation capacity of bridge transport vehicle | 100t X2 | 80t X2 | 60t X2 | 50t X2 | 50t X2 | ||

| heavy load speed of bridge transport vehicle | 8.5m/min | 8.5m/min | 8.5m/min | 8.5m/min | 8.5m/min | ||

| bridge transport vehicle return speed | 17m/min | 17m/min | 17m/min | 17m/min | 17m/min | ||

product details

country cases

philippines

HY Crane designed one 120 ton, 55 meters spanbridge launcher in the Philippines, 2020.

straight bridge

capacity: 50-250ton

span: 30-60m

lifting height: 5.5-11m

working class: A3

indonesia

In 2018, we provided one 180 ton capacity, 40meters span bridge launcher for lndonesia client.

skewed bridge

capacity: 50-250 Ton

span: 30-60M

lifting height: 5.5M-11m

working class: A3

bangladesh

This project was a 180 ton, 53 meters spanbeam launcher in Bangladesh, 2021.

cross the river bridge

capacity: 50-250 Ton

span: 30-60M

lifting height: 5.5M-11m

working class: A3

algeria

applied in mountain road,100 ton, 40 meters beamlauncher in Algeria, 2022.

mountain road bridge

capacity: 50-250 Ton

span: 30-6OM

lifting height: 5.5M-11m

working class: A3

application

- it is used in many fields.

- satisfy the users' choice under different condition.

- usage: used in factories, warehouse, material stocks to lift goods, to meet the daily lifting work.

- highway

- railway

- bridge

- highway

transport

- packing and delivery time

- we have a complete production security system and experienced workers to ensure timely or early delivery.

-

research and development

- professional power

-

brand

- strength of the factory.

-

production

- years of experience.

-

custom

- spot is enough.

-

asia

- 10-15days

-

middle east

- 15-25days

-

africa

- 30-40days

-

europe

- 30-40days

-

america

- 30-35days

By national station exporting standard plywood box,wooden palletor in 20ft & 40ft container. Or as per your demands.