Products

Best sale european electrical hoists for heavy load

Description

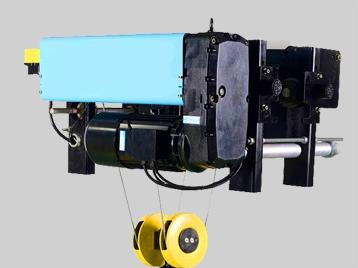

Europe style electric hoist is a cutting-edge solution

that revolutionized the lifting industry. With its superior design

and advanced features, this hoist has many advantages over

traditional models. Unlike traditional hoists, European style

electric hoists offer superior durability, efficiency and safety,

making them ideal for a wide variety of applications.

One of the main advantages of European style electric hoists is

their exceptional durability. Constructed of high-quality materials

and equipped with robust components, this hoist is able to withstand

the most challenging working environments. Its rugged construction

ensures long-lasting performance and reliability, reducing the need

for frequent maintenance and replacement parts. In addition, the

hoist's protective features such as overload protection and

emergency stop function enhance its durability and ensure the safety

of operators and equipment.

Another significant advantage of European electric hoists is

increased efficiency. Equipped with powerful motors and advanced

hoisting mechanisms, this hoist provides fast, precise lifting

operations, reducing valuable downtime. The smooth, seamless lifting

action of hoists enables fast and efficient material handling,

increasing productivity in a variety of industries. In addition, the

hoist's ergonomic design and user-friendly controls ensure ease of

operation, minimizing operator fatigue and optimizing workflow.

With its unique advantages, the European-style electric hoist brings

numerous application scenarios. Lifting heavy loads is a common task

in industries such as construction, manufacturing and logistics, and

this hoist is an indispensable tool. Its ability to handle heavy

loads with ease and precision makes it the perfect choice for tasks

involving the transport of machinery, construction materials or raw

materials. Furthermore, its versatility and adaptability allow it to

be used in a variety of environments, including workshops,

warehouses, assembly lines and ports.

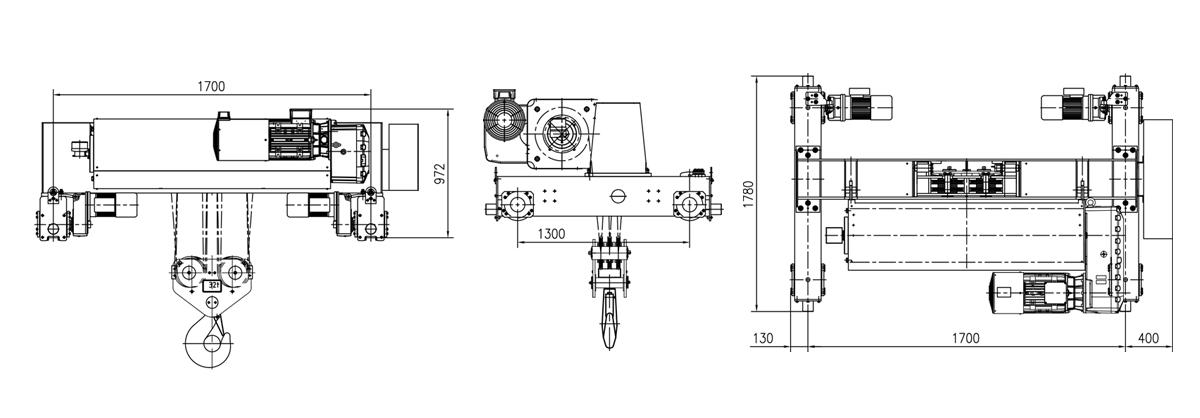

Technical Parameters

Manganese steel hook

After hot forging, it is not easy to break. The lower hook can rotate 360°

HY Crane

Providing you with the safest equipment

Solid shell

Solid and light, continuous use, high efficiency, integral sealed structure

Lifting drive

The noise pollution during motor operation is reduced.

| MAIN PARAMETERS | ||

|---|---|---|

| Item | Unit | Result |

| Lifting capacity | kg | 1000-12500 |

| Lifting Height | m | 6-18 |

| Lifting Speed | m/min | 0.6/4-1.6/10 |

| Trolley Speed | m/min | 2-20 |

| H | mm | 245-296 |

| C | mm | 385-792 |

| Working Class | FEM | 1Am-4m |

| Working Class | ISO/GB | M4-M7 |

Product Details

Drum

Electric Cabinet

Hook

Lifting Drive

Remote Control

Rope Guide

Wire Rope

Wheel

Fine Workmanship

We take great pride in the quality and workmanship of our

cranes and hoists as they are carefully designed and

built to meet the highest standards in the industry.

With a focus on

durability, efficiency and safety, our lifting equipment

is the perfect solution for all your heavy lifting

needs.

What sets our lifting equipment apart is our attention

to detail and commitment to excellence. Every component

of our cranes undergoes rigorous testing and quality

control measures to ensure optimum performance and

longevity. From precision crafted gantry systems to

robust frames and advanced control mechanisms, every

aspect of our lifting equipment is engineered with

precision and expertise.

Whether you need a crane for a construction site,

manufacturing plant or any other heavy-duty job, our

lifting equipment is the epitome of reliability and

efficiency. With their craftsmanship and superior

engineering, our cranes deliver exceptional lifting

capabilities, allowing you to move any load with ease

and confidence. Invest in our reliable and durable

lifting equipment today and experience the power and

precision our products bring to your operation.

HYCrane VS Others

Other brand:

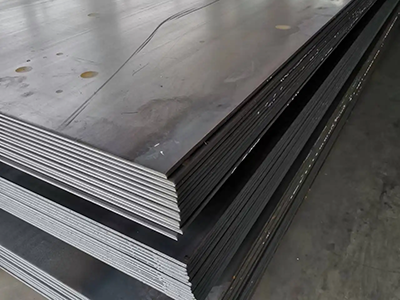

1. The raw

material

procurement

process is

strict and

has

been

inspected

by quality

inspectors.

2. The

materials

used are all

steel

products

from major

steel mills,

and

the quality

is

guaranteed.

3. Strictly

code

into

inventory.

Other brand:

1. Cut

corners,

such as:

originally

used

8mm steel

plate,

but used 6mm

for

customers.

2. As shown

in

the picture,

old

equipment is

often used

for

refurbishment.

3.

Procurement

of

non-standard

steel from

small

manufacturers,

product

quality

is unstable,

and

safety

risks are

high.

Our brand:

1. Motor

reducer

and brake

are

three-in-one

structure

2. Low

noise,

stable

operation

and low

maintenance

cost.

3. The

motor's

built-in

anti-drop

chain

can prevent

the

motor's

bolts

from being

loosened,

and

avoid the

harm

to

the human

body

caused by

the

accidental

fall

of the

motor, which

increases

the

safety of

the

equipment.

Other brand:

1.Old-style

motors: It

is

noisy, easy

to

wear, short

service

life,

and high

maintenance

cost.

2. The price

is

low and the

quality is

very

poor.

Our brand:

All wheels are heat-treated and modulated, and the surface is coated with anti-rust oil to increase the aesthetics.

Other brand:

1. Do not use

splash fire

modulation,

easy

to rust.

2. Poor

bearing

capacity and

short

service

life.

3. Low

price.

Our brand:

1. Adopting

Japanese

Yaskawa

or German

Schneider

inverters

not

only make

the

crane run

more

stable and

safe, but

also

the fault

alarm

function of

the

inverter

makes the

maintenance

of

the crane

easier

and more

intelligent.

2. The

self-adjusting

function of

the

inverter

allows

the motor to

self-adjust

its

power output

according to

the load of

the

hoisted

object

at any time,

which not

only

increases

the service

life

of the

motor,

but also

saves the

power

consumption

of

the

equipment,

thereby

saving the

factory Cost

of

electricity.

Other brand:

1.The control method of the ordinary contactor allows the crane to reach the maximum power after it is started, which not only causes the whole structure of the crane to shake to a certain degree at the moment of starting, but also slowly loses the service life of the motor.

Transport

HYCrane is a professional exported company.

Our products have been exported to

Indonesia,Mexico,Australian,India,Bangladesh,Philippines,Singapore,Malaysia,Pakistan,Sri

Lanka,Russia,Ethiopia,Saudi

Arabia,Egypt,KZ,Mongolia,Uzbekistant,Turkmentan,Thailand ects.

HYCrane will serve you with rich exported experience which can help you

save much trouble and help you solve many problems.

RESEARCH ANDDEVELOPMENT

Professional power.

BRAND

Strength ofthe factory.

PRODUCTION

Years ofexperience.

CUSTOM

Spot isenough.

Asia

10-15days

Middle East

15-25days

Africa

30-40days

Europe

30-40days

America

30-35days

By National Station exporting standard plywood box,wooden palletor in 20ft & 40ft Container.Or as per your demands.