Products

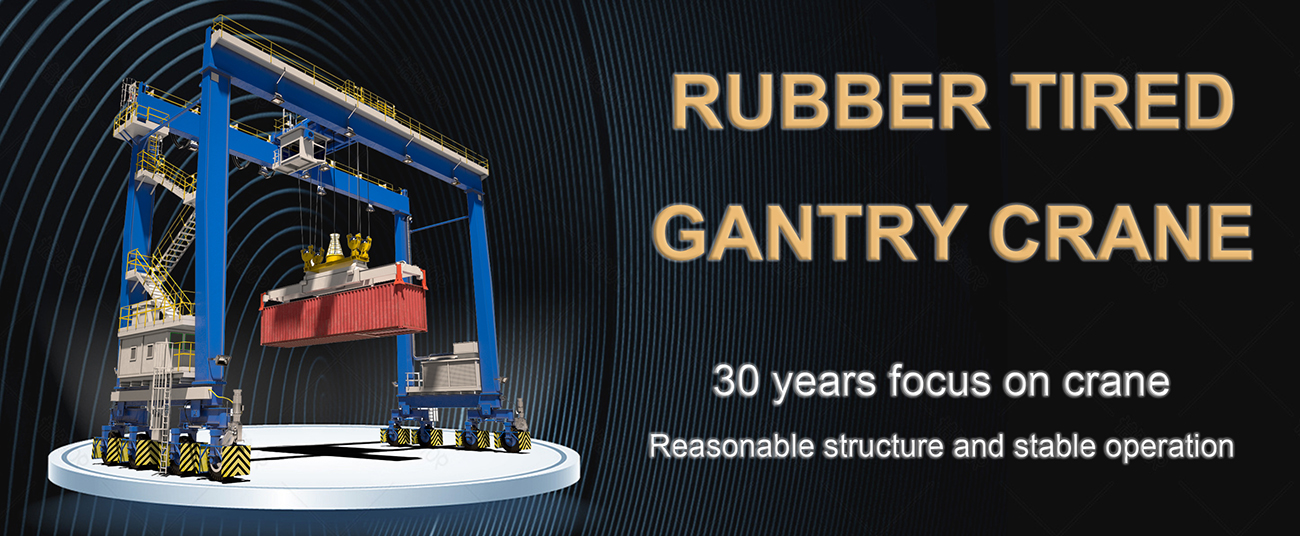

Best design stable container tyre wheel gantry crane for harbor

description

The significance of the rtg crane goes beyond its sheer strength and agility. It represents a new era in port operations, embracing advanced technology to streamline container handling processes. The rtg crane is equipped with advanced automation systems, including remote control capabilities and intelligent software for optimal positioning and container stacking. This level of automation not only enhances safety but also significantly increases productivity, enabling ports to handle larger volumes of cargo in less time.

In comparison to the rtg crane, has slight structural and operational differences. Instead of using rubber tires, the rmg crane is mounted on rails, providing a fixed track for its movement. This rail-mounted design offers greater stability, especially when handling heavy loads. The rmg crane is commonly used in large-scale container terminals, where it can efficiently handle multiple containers simultaneously. However, the limited mobility of the rmg crane restricts its usage to fixed rail tracks, making it less suitable for smaller ports or those with irregular layouts.

technical parameters

parameters of container rail mounted gantry crane |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| item | unit | result | |||||||

| lifting capacity | ton | 30.5-350 | |||||||

| lifting height | m | 15-18 | |||||||

| span | m | 18-50 | |||||||

| working environment temperture | °C | -20~40 | |||||||

| hoisting speed | m/min | 12-36 | |||||||

| trolley speed | m/min | 60-70 | |||||||

| working system | A6 | ||||||||

| power source | three-Phase ac 50HZ 380V | ||||||||

product details

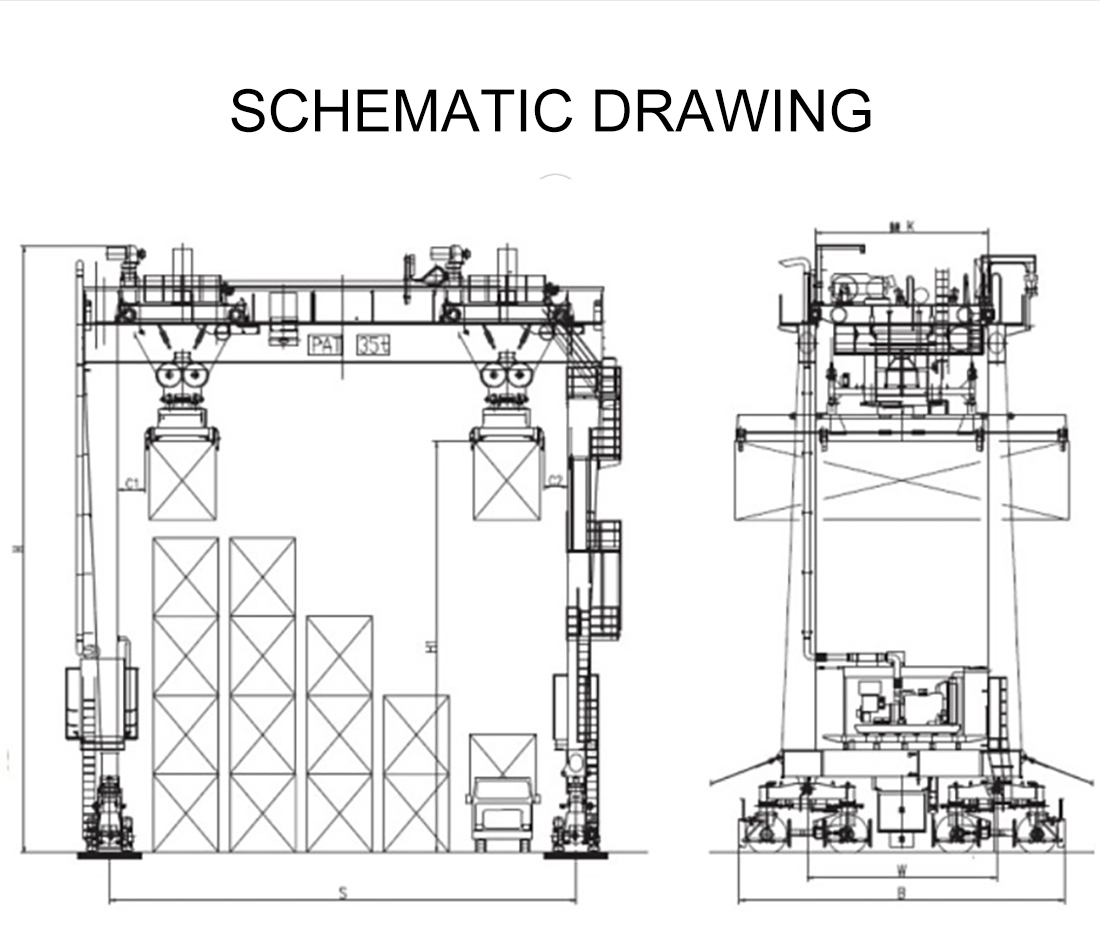

main beam

· with strong box type and standard camber

· there will have reinforcement plateinside the

main

girder

crane trolley

· high working duty hoist mechanism.

· working duty: a6-a8

· capacity:40.5t-70t.

container spreader

· reasonable structure, strong carryingcapacity, and can be processed and customized in 20ft to 45ft range expansion

cable drum

· the altitude does not exceed2000 meters.

· the protection class ofthe collector box is

ip54.

crane cabin

· Close and open type.

· Air-conditioning provided.

· Interlocked circuit breakerprovided.

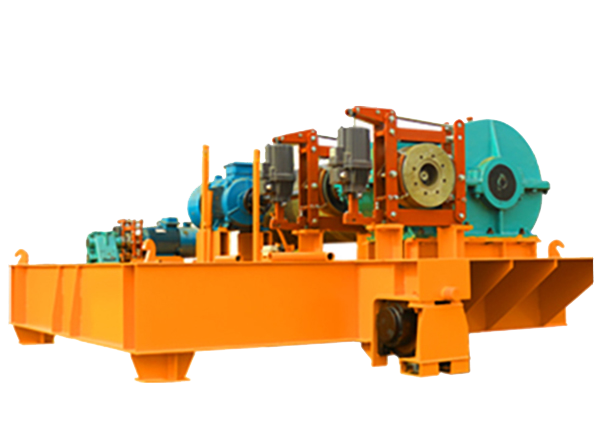

crane travelling machine

· material: ZG55, ZG65, ZG50SiMn oron request

· wheel diameter: 250mm-800mm.

Fine Workmanship

Low

Noise

Fine

Workmanship

Spot

Wholesale

Excellent

Material

Quality

Assurance

After-Sale

Service

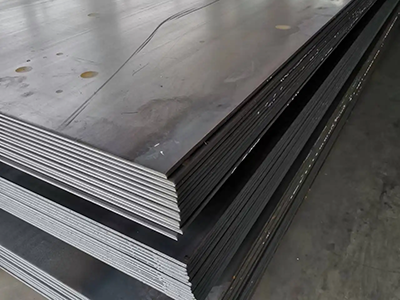

01

Raw Material

——

GB/T700 Q235B and Q355B

Carbon Strctural Steel, best quality steel plate from

China Top-Class mills with Diestamps inlude heat

treatment number and bathch number, it can be tracked.

02

Welding

——

American welding Society, all important welds are carried out in accordance with welding procedures strictly.After welding, a certain amount of NDT control is carried out.

03

Welding Joint

——

The appearance is uniform.The joints between the weld passes are smooth.All off the welding slags and splashes are cleared out. There are no faults such as cracks,pores,bruises etc.

04

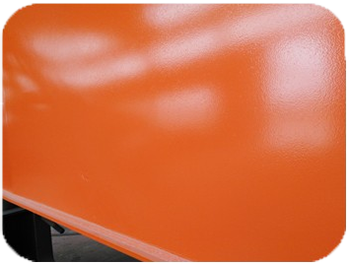

Painting

——

Before painting metal surfaces are shot peening sa required, two coats of pimer before assembly,two coats of synthetic enamel after testing. Painting adhesion is accorded to the class I of GB/T 9286.

HYCrane VS Others

Our Material

1. The raw material

procurement process is strict and

has been inspected by quality inspectors.

2. The materials used are all steel products from

major steel mills, and the quality is

guaranteed.

3. Strictly code into inventory.

1. Cut corners, originally used 8mm steel

plate,but used 6mm for customers.

2. As shown in the picture, old equipment is often

used for refurbishment.

3. Procurement of non-standard steel from small

manufacturers, product quality is unstable.

Other Brands

Our Motor

1. Motor reducer and brake

are three-in-one

structure

2. Low noise, stable operation and low maintenance

cost.

3. The built-in anti-drop chain can prevent

the bolts from being loosened, and avoid the

harm to the human body caused by the accidental fall

of the motor.

1.Old-style motors: It is noisy, easy to wear, short

service life, and high maintenance cost.

2. The price is low and the quality is very poor.

Other Brands

Our Wheels

All wheels are heat-treated and modulated, and the surface is coated with anti-rust oil to increase the aesthetics.

1. Do not use splash fire modulation, easy to

rust.

2. Poor bearing capacity and short service life.

3. Low price.

Other Brands

our controller

our inverters make the crane run more stable and safe, and make the maintenance of the more intelligent and easy.

the self-adjusting function of inverter allows motor to self-adjust its power output according to the load of the hoisted object at any time, thereby saving the factory costs.

the control method of the ordinary contactor allows the crane to reach the maximum power after it is started, which not only causes the whole structure of the crane to shake to a certain degree at the moment of starting, but also slowly loses the service life of the motor.

other brands

transport

- packing and delivery time

- we have a complete production security system and experienced workers to ensure timely or early delivery.

-

research and development

- professional power

-

brand

- strength of the factory.

-

production

- years of experience.

-

custom

- spot is enough.

-

asia

- 10-15days

-

middle east

- 15-25days

-

africa

- 30-40days

-

europe

- 30-40days

-

america

- 30-35days

By national station exporting standard plywood box,wooden palletor in 20ft & 40ft container. Or as per your demands.