Products

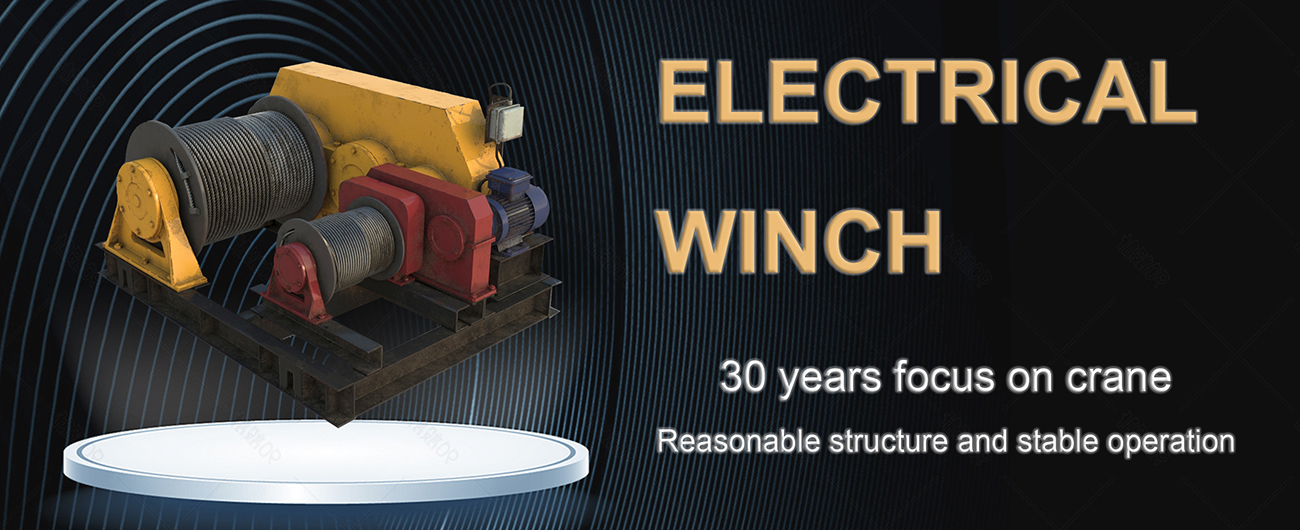

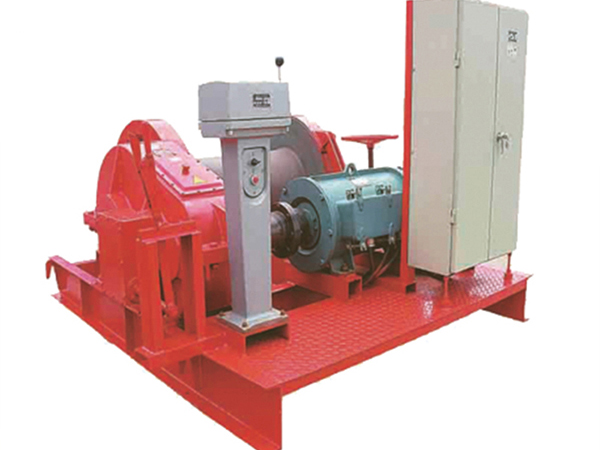

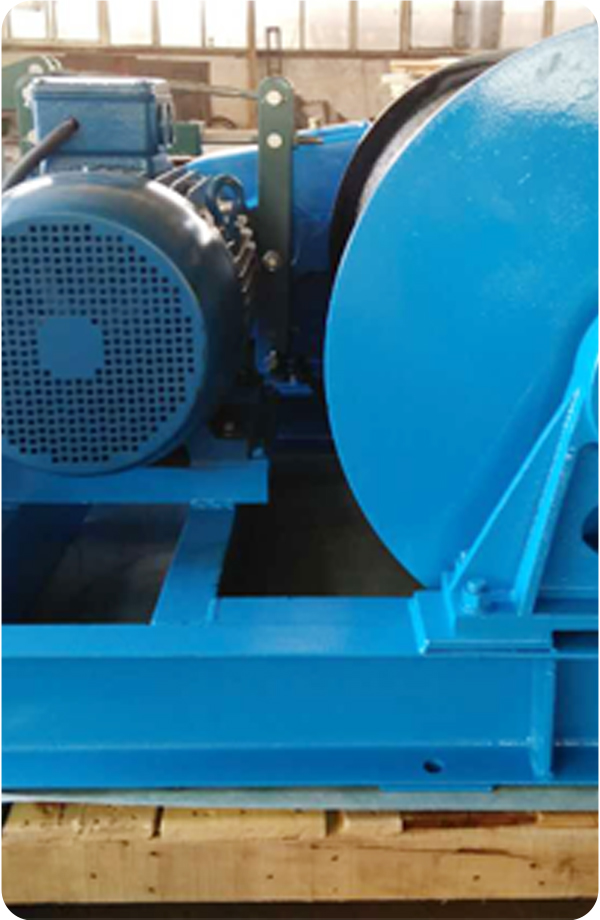

Advanced design electric winch machine with robust build

description

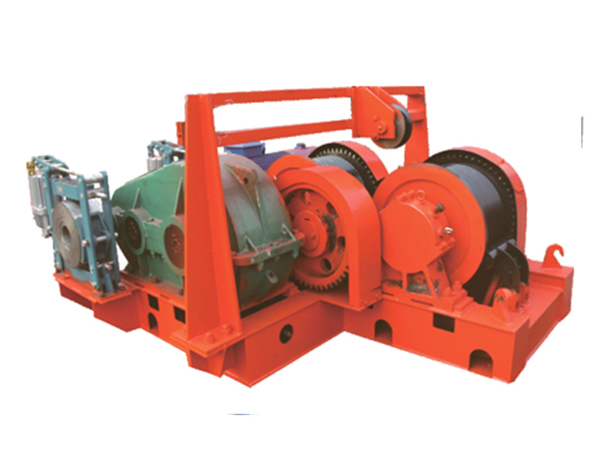

Electric winch machines are essential tools in various industries due to their unique advantages and well-designed features. These machines are characterized by their robust structure and versatile capabilities.

One of the notable structural features of electric winch machines is their sturdy construction. They consist of a high quality motor, a drum or reel mechanism, and a control system. The motor provides the necessary power to drive the winch, while the drum or reel is responsible for winding and unwinding the cables or ropes. Additionally, the control system allows for easy operation and ensures the safety of the winch.

The significance of electric winch machines extends to numerous industrial sectors. In the construction industry, these machines are utilized for lifting and moving heavy loads, making them indispensable for tasks such as erecting structures and handling materials. Similarly, in the marine industry , electric winches are used for hoisting anchors, handling cargo, and performing various tasks on ships. Moreover, electric winches find applications in the mining, forestry, and automobile industries, contributing to efficient and safe operations in these fields.

One of the key advantages of electric winch machines is their precise control. The advanced control systems allow operators to accurately regulate the speed and tension of the winch, ensuring optimal performance and preventing incidents or accidents. Furthermore, electric winches are known for their durability and reliability, enabling them to withstand harsh working conditions and deliver consistent results.

In terms of design, electric winch machines incorporate various safety features. These include emergency stop buttons, overload protection systems, and limit switches, which help protect both the operators and the equipment. Additionally, some models are equipped with remote control capabilities, providing convenience and flexibility in operation.

technical parameters

| parameters of electric winch machine | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| item | unit | specification | |||||||

| lifting capacity | t | 10-50 | |||||||

| rated load | 100-500 | ||||||||

| rated speed | m/min | 8-10 | |||||||

| Rope capacity | kg | 250-700 | |||||||

| Weight | kg | 2800-21000 | |||||||

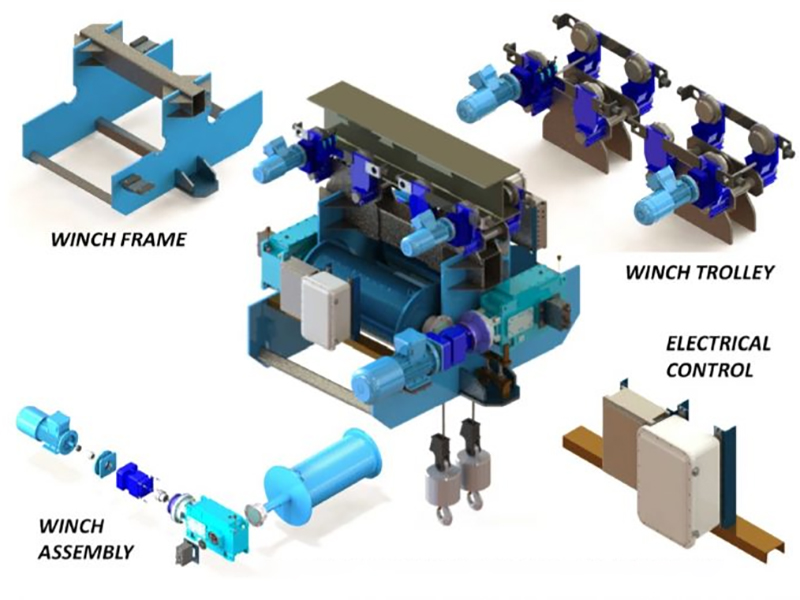

product details

motor

- · sufficient solid copper motor

- · the service life can reach 1 million times

- · high protection level

- · support double speed

drum

- · high quality alloy steel

- · special thickened steel wire rope drum

- · greater load bearing capacity and safer use

reducer

- · precision casting

- · protect internal parts

- · higher work efficiency

channel steel base

- · The base is thickened and reinforced, work more stably, safe and stable, and solve the trouble of shaking

HYCrane VS Others

Our Material

1. The raw material

procurement process is strict and

has been inspected by quality inspectors.

2. The materials used are all steel products from

major steel mills, and the quality is

guaranteed.

3. Strictly code into inventory.

1. Cut corners, originally used 8mm steel

plate,but used 6mm for customers.

2. As shown in the picture, old equipment is often

used for refurbishment.

3. Procurement of non-standard steel from small

manufacturers, product quality is unstable.

Other Brands

Our Motor

1. Motor reducer and brake

are three-in-one

structure

2. Low noise, stable operation and low maintenance

cost.

3. The built-in anti-drop chain can prevent

the bolts from being loosened, and avoid the

harm to the human body caused by the accidental fall

of the motor.

1.Old-style motors: It is noisy, easy to wear, short

service life, and high maintenance cost.

2. The price is low and the quality is very poor.

Other Brands

Our Wheels

All wheels are heat-treated and modulated, and the surface is coated with anti-rust oil to increase the aesthetics.

1. Do not use splash fire modulation, easy to

rust.

2. Poor bearing capacity and short service life.

3. Low price.

Other Brands

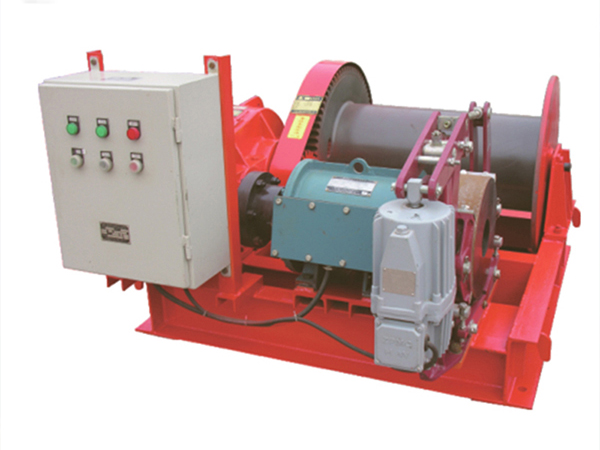

our controller

our inverters make the crane run more stable and safe, and make the maintenance of the more intelligent and easy.

the self-adjusting function of inverter allows motor to self-adjust its power output according to the load of the hoisted object at any time, thereby saving the factory costs.

the control method of the ordinary contactor allows the crane to reach the maximum power after it is started, which not only causes the whole structure of the crane to shake to a certain degree at the moment of starting, but also slowly loses the service life of the motor.

other brands

transport

- packing and delivery time

- we have a complete production security system and experienced workers to ensure timely or early delivery.

-

research and development

- professional power

-

brand

- strength of the factory.

-

production

- years of experience.

-

custom

- spot is enough.

-

asia

- 10-15days

-

middle east

- 15-25days

-

africa

- 30-40days

-

europe

- 30-40days

-

america

- 30-35days

By national station exporting standard plywood box,wooden palletor in 20ft & 40ft container. Or as per your demands.