About Us

About Us

Integrity and Innovation

HY Crane always adhere to the concept of integrity and innovation. Integrity makes the company lay a solid foundation and earn good reputation. Innovation is the inspiration that drives us to develop better and be a world class company.

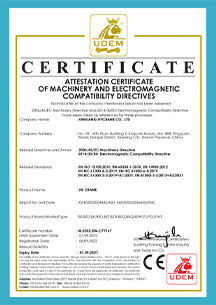

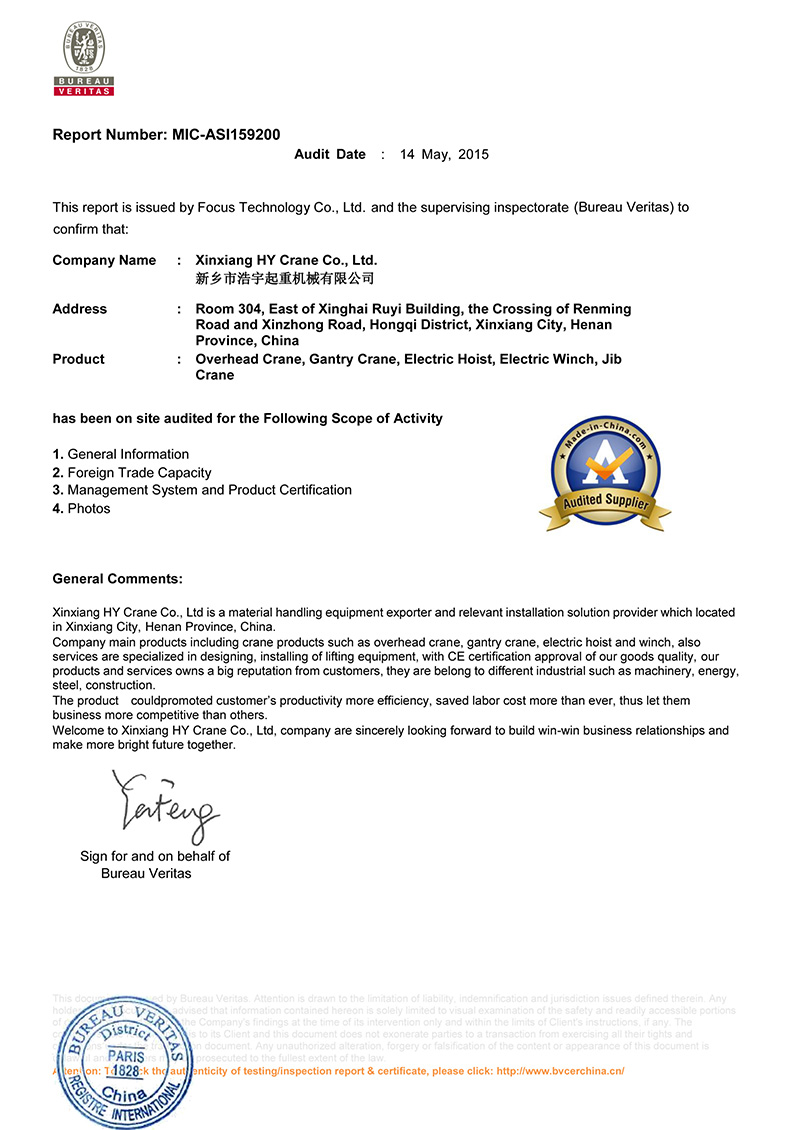

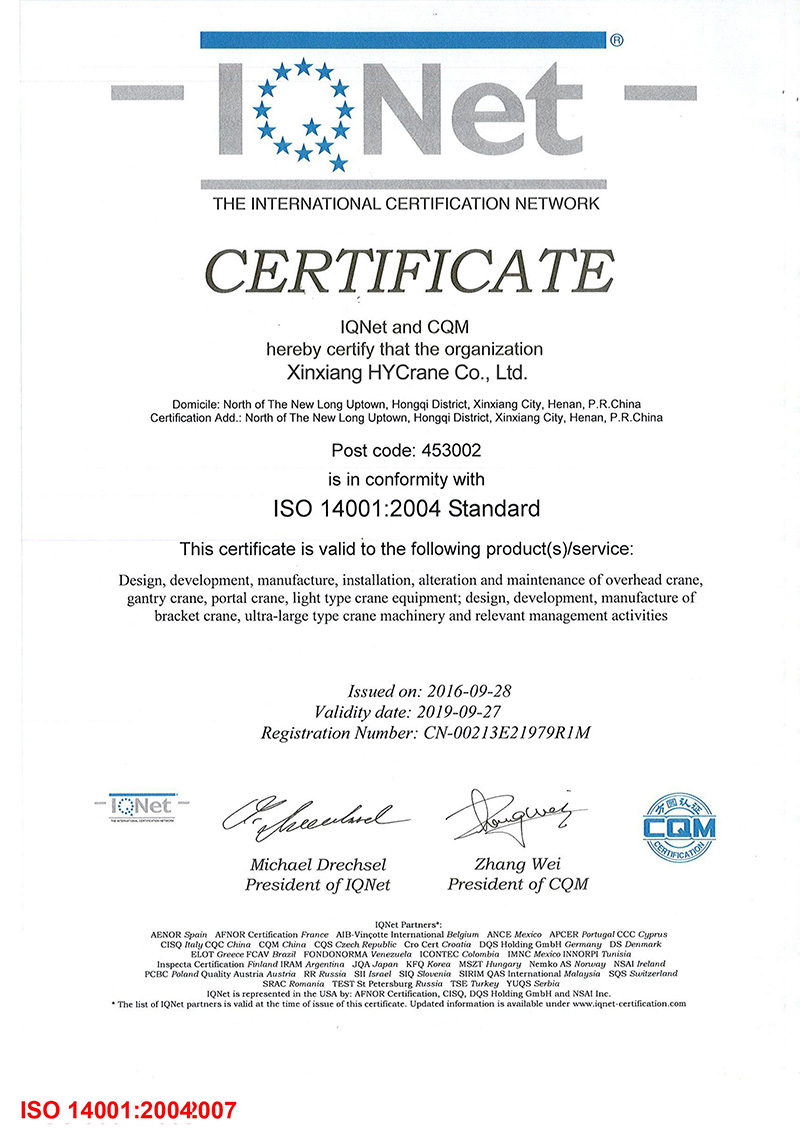

Quality and service

HY Crane owns its own technology and expertised engineer with abundant experience.We are also equipped with advanced automated machines to improve the quality of our product. Quality and service is always our core competence.

Factory Tour

- Modern Workshop

- Integrated Service

- Exhibition

Quality Control

- Crane Welding

- Crane Painting

- Crane Metal Cutting

- Crane Inspection

- Crane installation